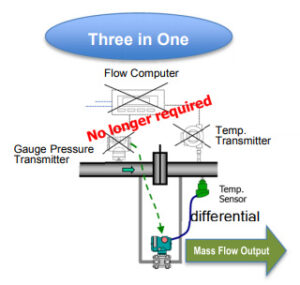

EJX Multivariable Transmitter successfully integrates the DPharp multi-sensing capability with an onboard flow computer and can be configured for multi-variable (DP, SP, T) or dynamically compensated mass flow outputs. Dynamic flow compensation allows the EJX Multivariable transmitter to eliminate inherent errors in the DP flow calculations at actual operating condition and to model the flow profile more precisely. Extensive range of primary elements and process fluids are supported. The EJX Multivariable Transmitter is compatible with a wide range of primary devices, including orifice plates, nozzles, venturi tubes, multiport averaging pitot and cone meters, and can be used with various types of fluid, including general fluids DIPPR, steam tables IAPWS-IF97 and natural gas standard AGA8/ISO12213.

EJX Multivariable TransmitterApplication information, such as the primary device and fluid data required for mass flow calculation, is using an FDT 2.0-based mass flow parameter configuration tool – FlowNavigator Flow Configuration Software FSA120 that runs on a PC and is downloaded to the transmitter by means of field communication. In operation, the flowmeter computes standard volumetric or mass flow from measured differential pressure (DP) and flowing density using actual measured pressure and temperature, unlike standard differential pressure transmitters which assume pressure and temperature – and therefore flowing density – to be constant.

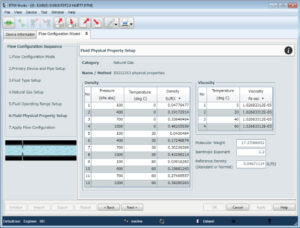

FlowNavigator Flow Configuration Software FSA120

New functions have been added to the YOKOGAWA Multivariable Transmitter EJX910A and EJX930A.

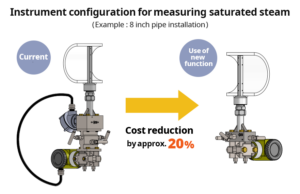

Saturated Steam Mode added for EJX Multivariable Transmitter

To reduce engineering man-hours and procurement costs, operation without using an external thermometer under saturated steam is made possible. The EJX Multivariable Transmitter can now calculate steam temperature from static pressure values using the steam table (international state formula IAPWS-IF97). When saturated steam mode (ET Fixed = Saturated Steam) is set, steam temperature values can be calculated. In measurement function B (mass flow measurement), saturated steam flow rate can be measured without connecting an external thermometer.

Storage of User Flow Parameters in FlowNavigator Flow Configuration Software FSA120

Application information, such as the primary device and fluid data required for mass flow calculation, is using an FDT 2.0-based mass flow parameter configuration tool, FlowNavigator. Users can now enter application information using FSA120 FlowNavigator R2.03 GUI (Graphic User Interface) allowing “User Flow Parameters” to be stored in the transmitter. This reduces man-hours required for equipment setup and management, enabling rapid start-up of operation. Previously, storage of “User Flow Parameters” in the transmitter was not possible.

“User Flow Parameters” entered using the FlowNavigator’s GUI include the primary device and fluid data required for mass flow calculation.

- Primary device and pipe setup

- Fluid type setup

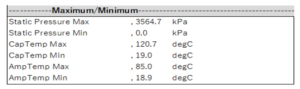

- Fluid operating range setup

- Fluid physical property setup

Fluid physical property setup

Display of Device History

Detailed equipment history information, including alarms and process data detected by the transmitter, can be displayed, and harvested via the EJX Multivariable Transmitter FDT 2.0-based-device DTM in the unlikely event of equipment failure. This provides improved maintenance operations by reducing the troubleshooting time required in the event of equipment failure.

The names of corporations, organizations, products, and logos mentioned in this article are either registered trademarks or trademarks of Yokogawa Electric Corporation and their respective holders.

Product case study contributed by Yokogawa Corporation