FDT Real-Time Supplement – May 2024 Issue | Navigating Industrial Device Management

In This Issue:

Discover the latest news and advancements in FDT/DTM development, which promise to streamline device management across all types of devices and communication buses. With FDT/DTM, managing diverse device ecosystems has never been easier.

- Editorial: FDT/DTM: The Collaborative Standard for Intelligent Device Management – Steve Biegacki

- Tech Focus: Revolutionizing Industrial Automation: The Impact of FDT and PI Technologies

- FDT / CodeWrights Interview – In a compelling interview, Sven Giesecke and Steve Biegacki delve into the profound impact of FDT/DTM technology on the industrial automation community and highlight CodeWrights’ solutions that support developers in achieving their goals.

- FDT Video: Importance of FDT/DTM for Ethernet/HART Applications – Rockwell Automation

- FDT Product: VEGA Expands Radar Portfolio for Factory Automation – VEGA

- FDT Services: FDT/DTM Development – One Platform All Device Types Using Any Bus – M&M Software

- Press Release: FieldComm Group and FDT Group Explore Strategic Business Collaboration

FDT Real-Time Supplement – March 2024 Issue | Fragmentation to Unity

In This Issue:

From overcoming integration hurdles to maximizing operational efficiency, this newsletter focuses on the pivotal role FDT/DTM technology enables in resolving intelligent device management challenges in control system applications across market domains, shaping the future of industrial innovation.

- Editorial: FDT/DTM Technology’s Role in Configuration – Steve Biegacki

- Tech Focus: FDT/DTM’s Flexibility in Integrating Hybrid Applications with EtherNet/IP and Modbus TCP Protocols

- FDT / Utthunga Interview: Interview with Utthunga (FDT Service Provider) focuses on how they help system and device vendors solve device integration challenges using FDT/DTM.

- FDT Product: New Compact5000 Analog HART DTM-enabled I/O – Rockwell Automation

- FDT Product: Yokogawa Adds New Functions to Oprex Field Instruments – Yokogawa

- Survey Results: Automation Community Seeks Industrial Control System Harmonization

- Press Release: FDT Group Certifies First FDT 3.0 DTM From Flowserve Corporation

FDT Real-Time Supplement – December 2023 Issue | Open to Innovation

In This Issue:

In our fast-paced and busy world, finding harmony is a journey. Although harmony can be challenging to achieve, working harmony will innovate.

In this issue, read how FDT/DTMs harmonize the data wave in heterogeneous environments for control applications, opening the door to modernization.

It’s the season of harmony! Happy Holidays, Merry Christmas and Happy New Year. We look forward to 2024!

- Editorial: DTM is the Heart and Soul of Intelligent Device Management – Steve Biegacki

- Tech Focus: DTM Opens HART to Modernization

- FDT / VEGA Interview: What FDT/DTM Technology Means to VEGA, Sensor and the Industry – John Groom, CEO and President of VEGA Americas

- FDT / M&M Software Interview: “FDT/DTM technology is a universal bridge that connects any device management scenario to any device under any fieldbus/protocol from any vendor.” – Pingsheng Xu – Development Group Manager, M&M Software

- FDT Product: DTM – Innovative Field Device Management – Schneider Electric

- FDT Product: Configure with FDT/DTM – Omron

- FDT Video: Paul Brooks – Rockwell Automation – Senior Manager, Technology and Innovation Group

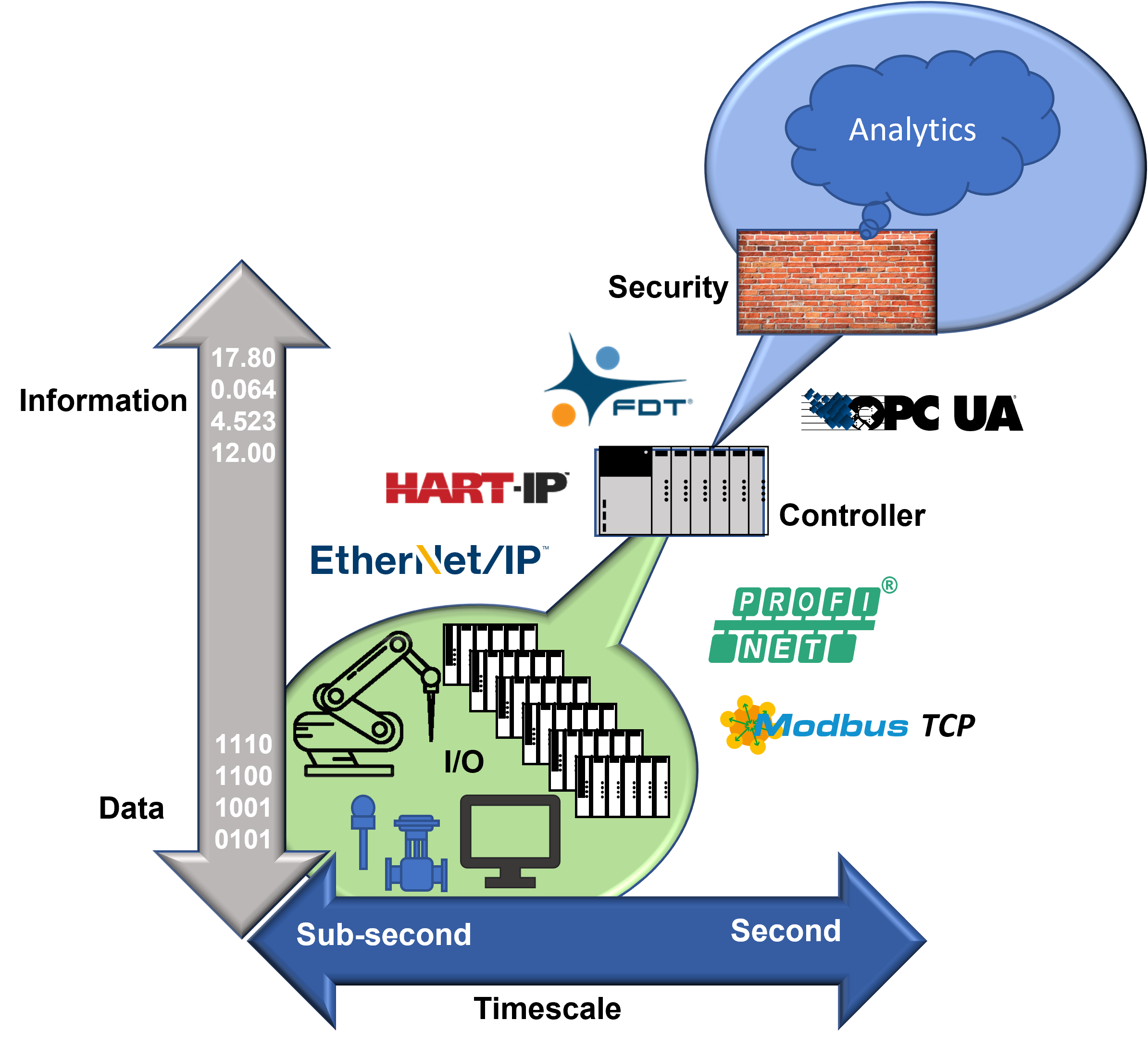

Unified Environment for Control System Integration

Common use of open standards lay the foundation for interoperability

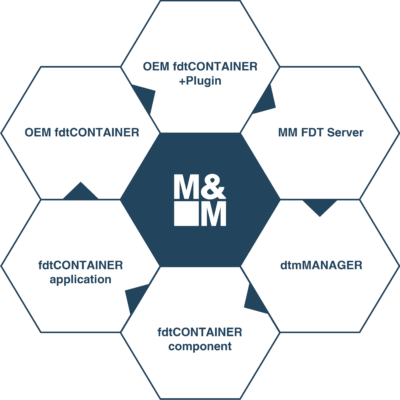

Meet M&M Software’s Full Stack Now Supporting FDT UE

Strengthen Integration of Automation Components with FDT/DTM

M&M Software Announces Release of fdtCONTAINER and Developer Tools Supporting FDT 3.0

Migration path for users and vendors supporting modern intelligent device management and monitoring initiatives

FDT Group Introduces FDT UE Developer Tool Evaluation Software

Speed FDT UE-enabled systems and devices to market supporting modern industrial device management

Accelerate Your Reliability-Centered Maintenance Strategy

Capitalizing on existing data-centric technologies enables better predictive maintenance practices and uncovers manufacturing efficiencies – delivering immediate value and long-term savings.

PACTware 6.1 Now Supports FDT3 and Expands Device Integration Model

Upgraded configuration environment features backwards compatibility and adds support for FDT3 web-based DTMs and FDI Device Packages

Editorial: Data Harmonization on Course for the FDT Unified Environment

Deeper communications and collaborations define one standard for device management