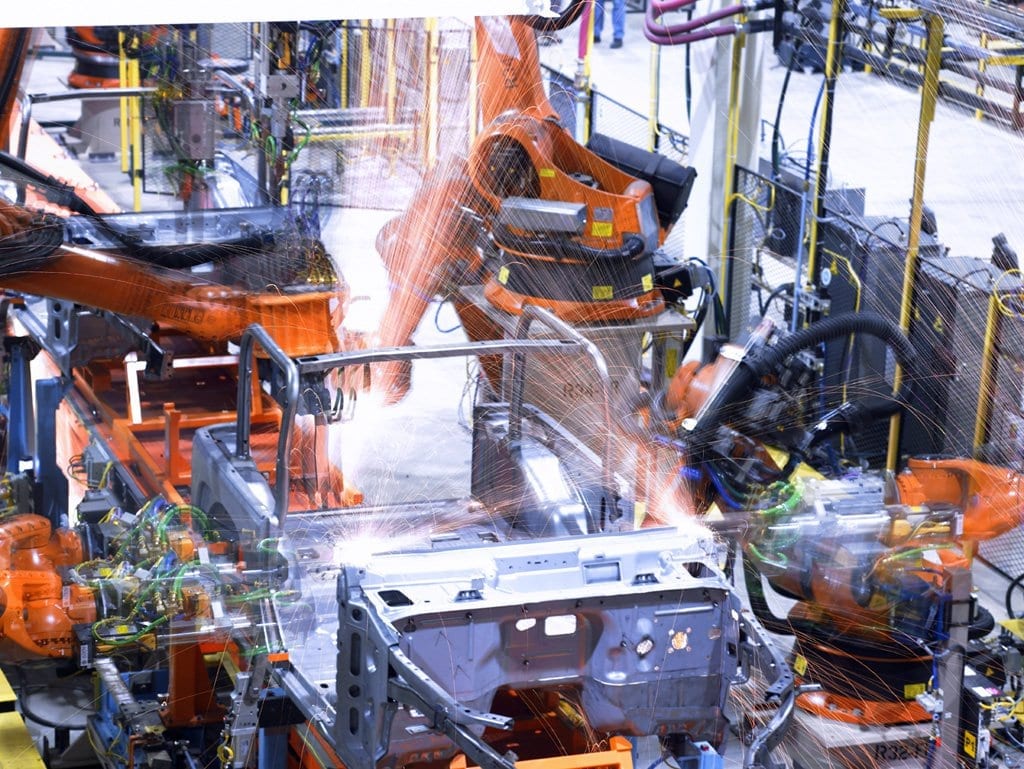

Pulp Plant Slashes Valve Maintenance Costs

In This Issue:

- Major Pulp Plant Slashes Maintenance Costs and Downtime,

- To Repair or Replace the Device – That’s the Question,

- Gateway Provides a Bridge Between Measurement and Maintenance,

- Configuring, Calibrating HART Devices Made Easy,

- One Software Environment, Myriad Functions,

- FDT Offers Device Setpoint Confidence,

- Seamless Data Exchange Across All Network Layers and Protocols