Author: Dr. Vivek Hajarnavis – Technical Marketing, FDT Group

In the industrial automation sector, the Human-Machine Interface (HMI) for plant or factory operations must be optimized to ensure the best possible user experience. New HMI’s must blend graphic design, human psychology and machine technology all while maintaining a uniform look and feel across all supplier solutions to execute effective asset management practices.

The User Interface (UI) design for measurement and control applications has critical importance within modern industrial operations, as it leverages operator behavior and machine communication together delivering the best “human-centric” user interface experience possible.

User interface design for today’s web-based environment isn’t just about buttons and menus; it’s about the interaction between the user and the application or device, and in many cases, it involves the interaction between multiple users through that device.

Experience has shown that a well configured UI is key to ensuring an effective user experience (UX) with industrial automation systems. And the design of an optimized Web UI requires adherence to a Style Guide, which is a development tool that brings cohesion to a digital product’s user interface experience. Style Guides employed for Web UIs focus on intuitive user interactions – ensuring that the interface has elements that are consistent, uniform, and easy to access and understand.

Recent advancements of FDT technology have helped to optimize HMI solutions as part of new, innovative business models for automation suppliers. They are driving secure remote access, real-time remote operations and modernized asset management strategies for industrial end users around the world.

Figure 1. Advancements of FDT technology have helped to optimize HMI solutions for modern plant and factory operations.

Understanding the FDT 3.0 Standard

FDT Group, founded by a group of automation manufacturers during the Third Industrial Revolution, developed FDT technology as an open, integration standards-based solution to fix interoperability issues for control system and device end users. The FDT standard has been defining UIs for industrial automation users since its creation, and today it is widely deployed as the industry’s de-facto integration platform.

The newly launched FDT 3.0 standard builds off its solid foundational base and brings enhancements empowering an FDT Server with embedded OPC Unified Architecture (UA) and Web Servers. The standard supports digital transformation for manufacturers seeking an innovative technology that supports new business models by enabling an open, enterprise-wide, IIoT data-centric integration platform offering built-in security and features to mobilize real-time remote operations.

For suppliers of industrial control products and solutions, implementation of the FDT 3.0 standard is the forward-looking strategy supporting the new era of automation. FDT technology has evolved to support the Industrial Internet of Things (IIoT) and Industry 4.0, including applications opening the door for standardized skid-to-cloud architectures while providing sensor-to-enterprise-wide integration.

The FDT IIoT Ecosystem consists of a platform agnostic FDT Server and FDT Device Type Manager™ (FDT/DTM™). Both components are essential to unlocking universal device integration and a data-centric platform to mobilize the industrial workforce with modern and diverse deployment options, including cloud, enterprise, edge, on-premise, and single-user desktop environments.

The FDT Server is a pivotal IIoT hub empowering the intelligent enterprise. This distributive, multi-user server solution employs a web services portal allowing access from authenticated mobile devices or any major browser along with an OPC UA Server for enterprise access to real-time plant floor data. Its rich features ensure any industrial communication protocol or vendor device can be seamlessly integrated as part of smart manufacturing practices.

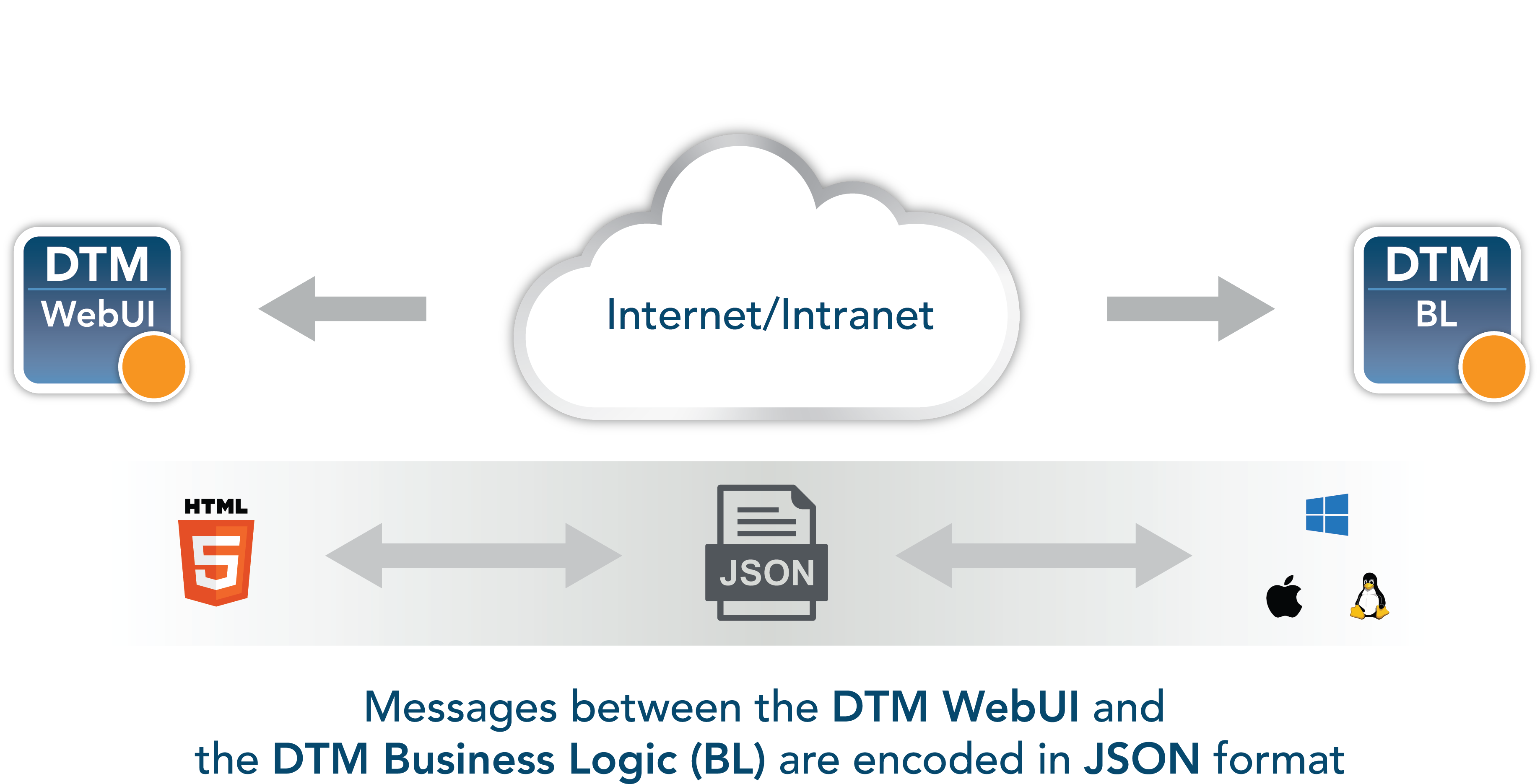

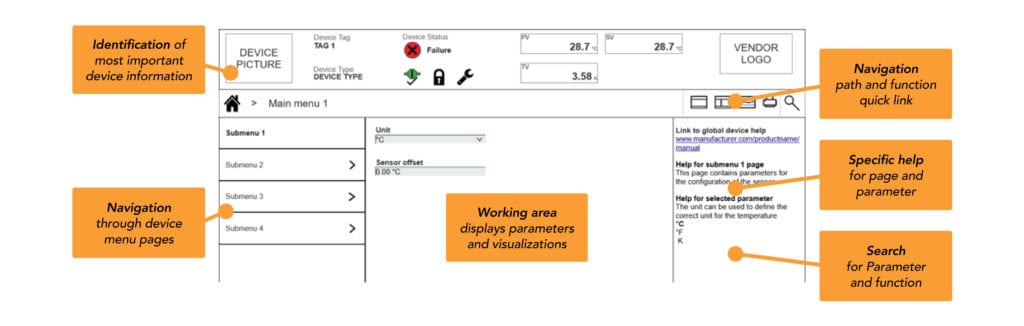

FDT 3.0 technology encompasses several essential classes of DTMs: Device DTMs, Universal DTMs, Interpreter DTMs, Communication DTMs, and Gateway DTMs. The DTMs within FDT 3.0 are essential for the visualization of smart devices across the enterprise. They contain the business logic software that defines online and offline parameters—device model and bus mapping for each automation device. FDT/DTMs encapsulate all device-specific data, functions and business rules. These standardized “drivers” are enabled with a customizable web UI employing HTML 5.0 and JavaScript focused on displaying a graphical representation of parameterization, diagnostic and prognostics across mobile devices and browsers. Although the DTMs’ appearance and functionality are engineered by the device vendor, they conform to the FDT standard to provide a common structure across all manufacturers.

New Style Guide Optimizes DTM Visualization

The FDT user interface is tried and proven for efficiency due to its ease of use. Recent technology developments have enhanced its overall UX with a standardized Web UI, which optimizes visualization of DTMs and enables the implementation of robust remote monitoring and control solutions within industrial plants and factories.

The new generation of FDT DTM-based Web UIs combine the best features of traditional HMI solutions with the utilization of modern open-source hardware, software, and networking technologies to address long-standing developer issues related to proprietary hardware and software, and maintainability. These Web UIs allow developers to implement state-of-the art functionality such as touch-capable virtual keyboards, touchpads and mouse-and-keyboard solutions. In addition, a set of frameworks to integrate dynamic variables employing modern HTML technology allows for less writing of code and more functionality.

The FDT 3.0 IIoT Ecosystem development environment, known as FDT Common Components, simplifies the journey to innovative IIoT and I4.0 solutions by enabling automation system and device suppliers to take a well-established standard and create customized, data-centric, cross-platform FDT solutions. This ecosystem includes an updated FDT 3.0 Style Guide empowering a standardized, responsive-by-design web user interface for new solutions developed by the supplier community. No other standard offers a more comprehensive, template-based approach for the industrial UI.

FDT Group is the first industrial standards organization to require Style Guide compliance for automation developers as part of its product certification process. It is also the first organization in the automation market to include responsive technology features in its style document. Style guide and DTM compliance go hand-in-hand with FDT 3.0.

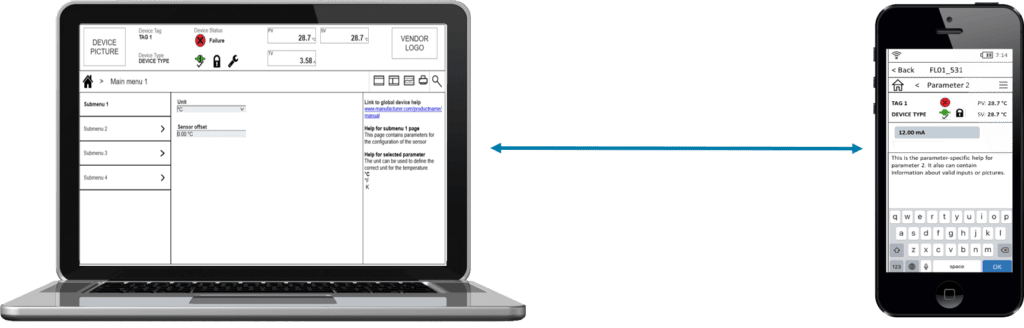

With the FDT 3.0 standard and its updated Style Guide, the approach to the DTM interface includes a completely uniform, responsive design focused on mobilizing secure remote access independent of the device, system, browser, phone, operating system, etc. The Style Guide describes elements of the automation interface in the HTML5 JavaScript world, so it is based on a state-of-the-art approach. The FDT 3.0 Web UI is suited to a new generation of workers who are digital natives and expect to use web-oriented technologies.

Figure 2. The FDT/DTM Web User Interface.

Benedikt Spielmann, marketing manager for industrial communications, Endress + Hauser, has been closely involved with Style Guide updates as part of the FDT 3.0 standard development effort. He said, “The goal of our FDT working group was to create a Style Guide that helps users of FDT-enabled systems do their jobs more efficiently with a modern graphical user interface. We wanted to ensure a uniform UI with the same look and feel, presenting information in a consistent fashion across different vendors, devices and applications. This is especially important with new mobile solutions being deployed in industrial facilities.

“From a vendor perspective, the new Style Guide drives digitalization while helping to reduce development effort and maintain interoperability. It establishes a graphical format for creating a standardized interface for DTMs that is already embedded and accepted in the industry. This, in turn, results in greater acceptance among end customers.”

Spielmann added, “The new FDT standard makes full use of HTML5 technology and offers true platform independence. This approach offers many more opportunities for DTM developers to implement the best possible UI, and thus provide the best available user experience to their customers. By supporting responsive designs, the updated Style Guide helps developers maintain an optimal viewing experience across all screen formats on mobile devices, whether it be tablets, cell phones or remote PCs.”

Figure 3. DTM Layout Overview.

Style Guide conformance is required for a standardized/uniform approach for FDT 3.0 DTMs—all major navigation and information points are presented in the same fashion, no matter the manufacturer, device or device type. Additionally, all FDT 3.0-compliant DTMs show NAMUR NE 107 status symbol recommendations for improved predictive maintenance, diagnosis and issue resolution. FDT provides a single interface with the same look and feel, which is responsive by design to create the best UX for interfacing with each device. Its Web UI is streamlined and efficient for asset management and optimized maintenance strategies.

Figure 4. New FDT 3.0 DTMs employ a responsive design approach for use with all types of mobile devices.

Delivering Benefits for Developers and End Users

Ultimately, the new FDT 3.0 Style Guide gives DTM developers a templated way of utilizing responsive designs in their products to meet market criteria for the new era of automation. End users benefit from greater consistency in terms of device navigation, as well as a uniform graphical user interface providing intuitive interactions for effective day-to-day monitoring activities.

Automation suppliers can obtain the updated FDT 3.0 Style Guide and other development tools directly from FDT Group and access the necessary licenses and specifications for their development initiatives. Specification licenses are mandatory for FDT 3.0 development (FDT Group members receive significant discounts on these items). Additionally, all DTMs are certified under the new FDT 3.0 standard requirements. They are the driving force for the standardized IIoT ecosystem for sensor-to-cloud and enterprise-wide interoperability.