Today’s operators in large and small industrial processing facilities remain challenged to make informative decisions due to a lack of access to data consistency. Uptime is money, and as we work to improve efficiencies in an already fast-paced environment, access to device diagnostics in a snapshot to make timely decisions is mandatory.

Achieving access to available device data is critical to maintaining plant health and overall performance. To accomplish standardized visualization of device/process health, a complete portfolio of DTM enhanced HART I/O modules are available. Rockwell Automation®, a leading provider of I/O solutions for smart devices, provides the ability to scale control and I/O solutions to match your application requirements and level of device intelligence.

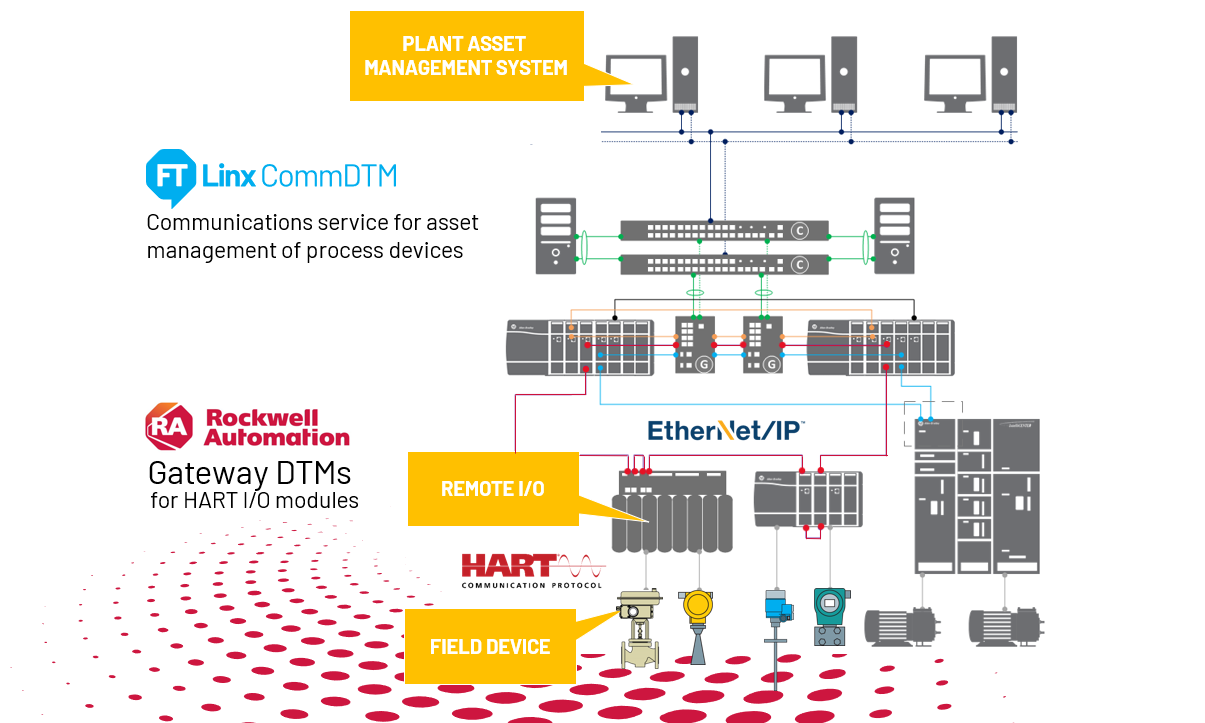

Rockwell Automation is committed to providing DTMs for their I/O platforms including 1756, 1794, FLEX 5000, and AADvance®. Device DTMs unlock a universal approach to intelligent device management and streamline monitoring of all connected devices in the industrial space with centralized instrument and asset management systems. Utilizing DTMs, users can gain better visibility into I/O platform performance, enable remote connectivity to data-centric field devices, manage configuration, and monitor device diagnostics according to the NE 107 recommendation.

HART-enabled I/O platforms deliver access to information originating on the plant floor via real-time control systems and information-rich business and analytical systems. With device health and data consistency funneled transparently through different communication channels, it streamlines the workflow allowing operations and business management teams to make informed decisions based on historical performance and performance trends.

Rockwell Automation HART I/O DTMs provide device intelligence and efficiency when configuring your plant network. System engineers can now scan the field device network for I/O adapters, I/O modules, and connected field devices. Automatic scans simplify the workflow with a fast connection eliminating the need for data entry and possible entry mistakes that consume precious time to troubleshoot and fix. Additionally, automated field network scans improve design setup efficiency including integrating skids from varying manufacturers or adding a skid to the system configuration once the control network is connected to the I/O platform on-site. The scan can identify all field devices connected to the I/O prior to shipment of the skid without on-site personnel needing to configure the devices individually.

The advantages of using multiple I/O platforms for your varying application requirements like mounting locations, I/O density, and safety ratings can be used within the same project using the Rockwell Automation FactoryTalk® Linx CommDTM. The CommDTM provides easy and fast connectivity to a wide variety of I/O platform adapters. This enables the existing plant infrastructure local or remote access to the plant floor alleviating the need for maintenance technicians to have specialized cables to connect field devices. DTMs keep workers safe and limit the number of trips to the field by enabling remote access to the device configuration and diagnostic data.

Visit our Product Compatibility and Download Center (PCDC). To download the FactoryTalk® Linx Comm DTM or other device DTMs for our I/O families, click “Downloads” and search for “DTM”.

Learn more about industrial communication at Rockwell Automation.

FDT Product Case Study contributed by Rockwell Automation.