Summary:

One leading industrial automation giant, specialized in manufacturing, production, and lifecycle services for valves, actuators & regulators, and other plant assets faced practical difficulty in configuration and maintenance of their various field devices. Utthunga developed a single Device DTM, which reduced the operational time and time to market while ensuring compliance with FDT 1.2 standard.

Challenge:

Client is the manufacturer of a wide variety of industrial products including smart valve positioners, ball and sliding stem valves, steam conditioning equipment, and actuators.

They needed to develop a Device Driver/Device Type Manager (DTM) that allows the user to:

- Perform Device Setup for 150+ Actuator types, Partial & Full Stroke methods

- Monitor the health check of the instruments

- Configure the input/output configuration parameters

- Extend the instrument’s monitoring and diagnostic capabilities

They wanted their device driver to be complaint with the FDT 1.2 standards to operate in various FDT/FRAME applications including DCS. It was a crucial time for them to deliver the device driver to the market with very limited duration.

Solution:

Based on the requirement analysis, the end user environment, and needs, Utthunga proposed below solutions for the client’s challenges.

- Create mock-ups for complex methods like Device Setup, Auto Tuning, Stroke Value, Linearization, and Calibration. The actual Device Setup method flow had 100+ screens, which had been simplified into 20+ screens without changing any algorithm or the flow of the method logic.

- Develop the Device DTM to meet FDT 1.2 standard and PROFIBUS PA Profile with 3.02 compliance and related attributes shall be added in the Device DTM for identification purpose.

- Perform pre-compliance testing to reduce time spent for fixing the issues during the FDT certification process.

- Provide a better user experience and usability by following Human Centered Design to reduce the duplicate screens and methods.

- Set up the test environment to work with the existing Device Description and to have complete understanding of the device functionality.

- Provide multiple language support with very minimal development efforts by only providing the resource strings in XML.

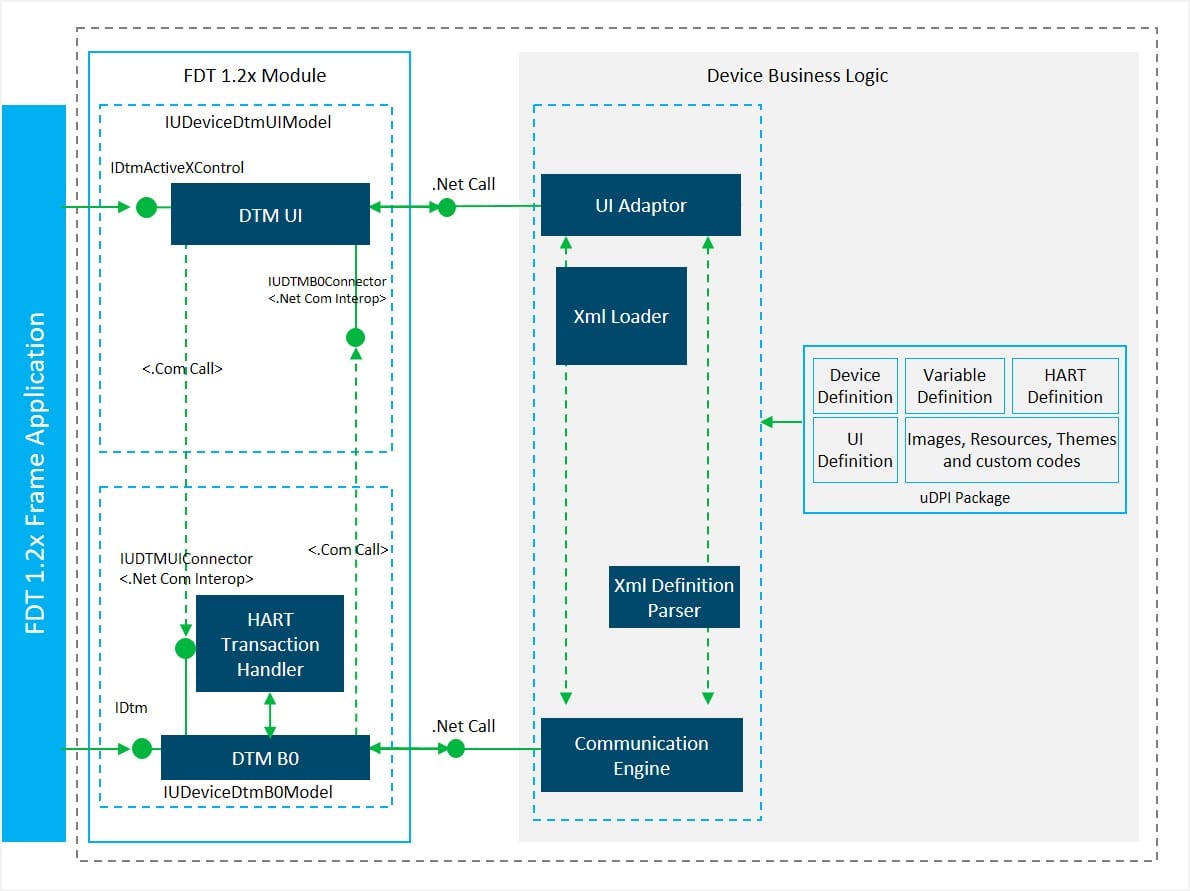

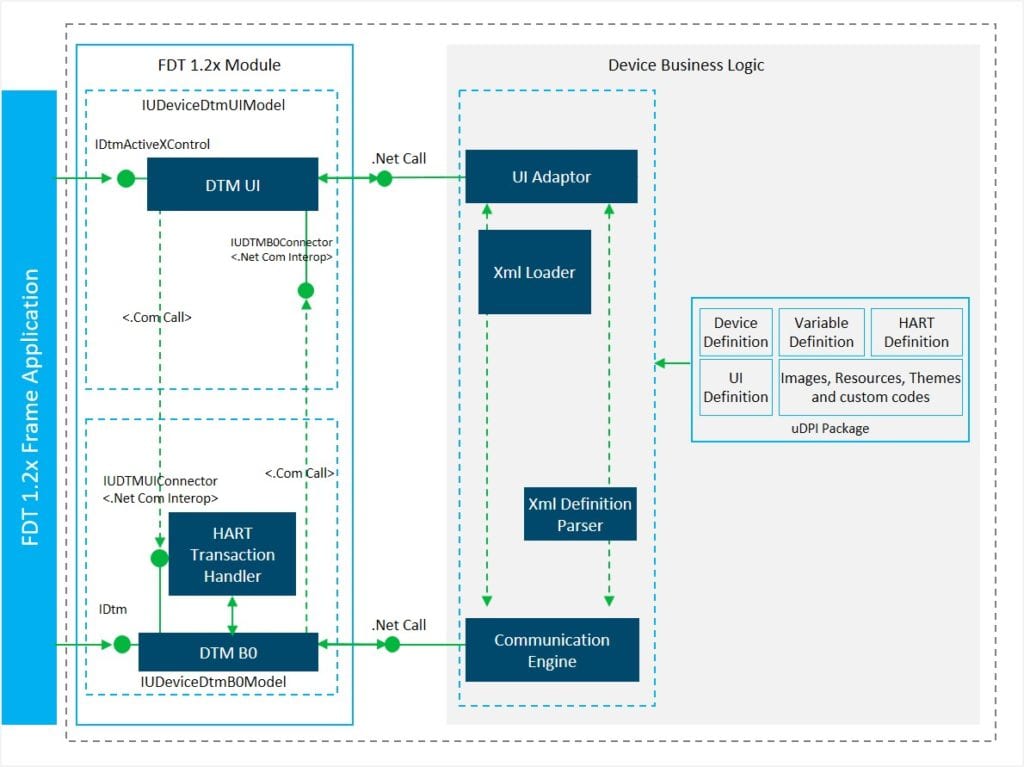

Internals of uDTMsdk, Utthunga’s proprietary DTM development framework

Result:

The client was able to achieve tangible benefits in various aspects:

- The single Device DTM shall be used to work with 150+ Actuator types and Actuator sizes.

- Quick and on-time demonstration/deployment of the device DTM resulted in gaining the trust of new customers and actively engaging them.

- Reduced the development efforts for this project from 12 months to 7 months while providing high quality deliverables using Utthunga’s proprietary framework, uDTMsdk.

- Reduced the time spent for executing the complex methods flow, which in turn saved time during commissioning.

- Same device configuration can be loaded to N number of device by using upload & download operations.

For more details on our FDT solution visit our website www.utthunga.com or email us [email protected].

Authored by: Ms. Divya Selvakumar, Utthunga

Authored by: Ms. Divya Selvakumar, Utthunga

Email: [email protected]