Author: James Loh Chia Woon, FDT Test and Certification Chairman

Modern developer tools, comprehensive testing and new online DTM repository streamlines certification process for manufacturers and improves DTM access for end users.

As an independent, international, not-for-profit industry association, FDT Group has developed and maintained an open standard for enterprise-wide network and asset integration in the process, hybrid and factory automation markets.

The organization’s new, forward-looking FDT 3.0 standard is accelerating its evolutionary journey into the Fourth Industrial Revolution. The technology’s FDT IIoT Server platform holds the key to unlocking universal device integration.

As a core component of the FDT standard, Device Type Managers™ (DTMs™) contain the user interface and the application software that defines all the parameters and capabilities included in field instruments. DTMs encapsulate all device-specific data, functions and business rules such as the device structure, its communication capabilities, internal dependencies, and its human-machine interface (HMI) structure.

As part of FDT Group’s comprehensive DTM testing process, accredited test sites test DTMs against the current FDT specifications. DTMs that are compliant with the specifications allow open access to intelligent devices and the myriad of information available from those devices, networks, and plant and factory processes.

Recent updates to FDT Group’s test tools and certification procedures are aimed at optimizing the efforts of DTM developers and helping them bring new products to market, while at the same time improving the experience of automation end users around the world. As the technology evolves so do the test and certification procedures enabling the process to be more automated and secure. The new steps in FDT 3.0 DTM certification are streamlined for a better overall experience.

Understanding DTM testing and certification

Certification to the FDT specification is a process whereby rigorous compliance testing ensures the viability of the states of the DTM; its correct installation, de-installation and multi-user environment capability; mandatory and optional interface functionality and robustness; network scanning communication performance and the ability to import and export the topology; and the audit trail capability.

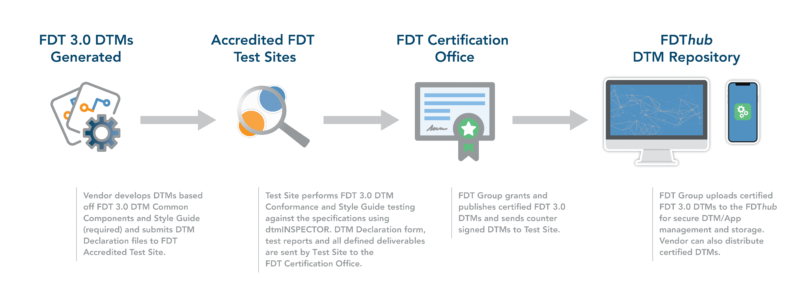

Once an FDT-accredited test site determines that a DTM has passed the necessary testing, it submits all Declaration Files to the FDT Group Certification Office. The DTM then receives the official DTM certificate that is sent to the vendor along with the FDT Certified logo acknowledging compliance.

Key to the development of FDT-compliant DTMs is the use of FDT Group’s Common Components toolkit, which provides a fast way for development teams to view DTMs in an FDT hosting (Desktop or Server) application and understand the communication flow between them. The toolkit’s Web User Interface (UI) allows them to see how different DTMs work together across various machines and operating systems.

With FDT 3.0, DTMs are now OPC UA-ready and offer data through the natively-integrated FDT OPC Unified server. This feature eliminates a significant amount of effort on the part of developers, who can implement FDT 3.0 using the Common Components and then rely on the toolkit’s clear guidance to support interfaces within the standard.

Figure 1: Updated FDT 3.0 DTM Certification Process

Device suppliers can also use a tool known as dtmINSPECTOR to automate and streamline DTM certification procedures. This tool ensures that any new script for DTM development is compliant with the FDT specifications. It enables developers to run internal tests to identify technical issues prior to submitting their DTM to an independent test site for certification. The test site uses the same version of the tool to run conformance test cases and generate a report on their results.

The dtmINSPECTOR software aligns with the DTM Common Components toolkit, providing developers with pre-written and pre-tested FDT specification requirements to speed the product development, testing and certification process. This approach simplifies DTM testing since the Common Components inherently meet many of the required test cases.

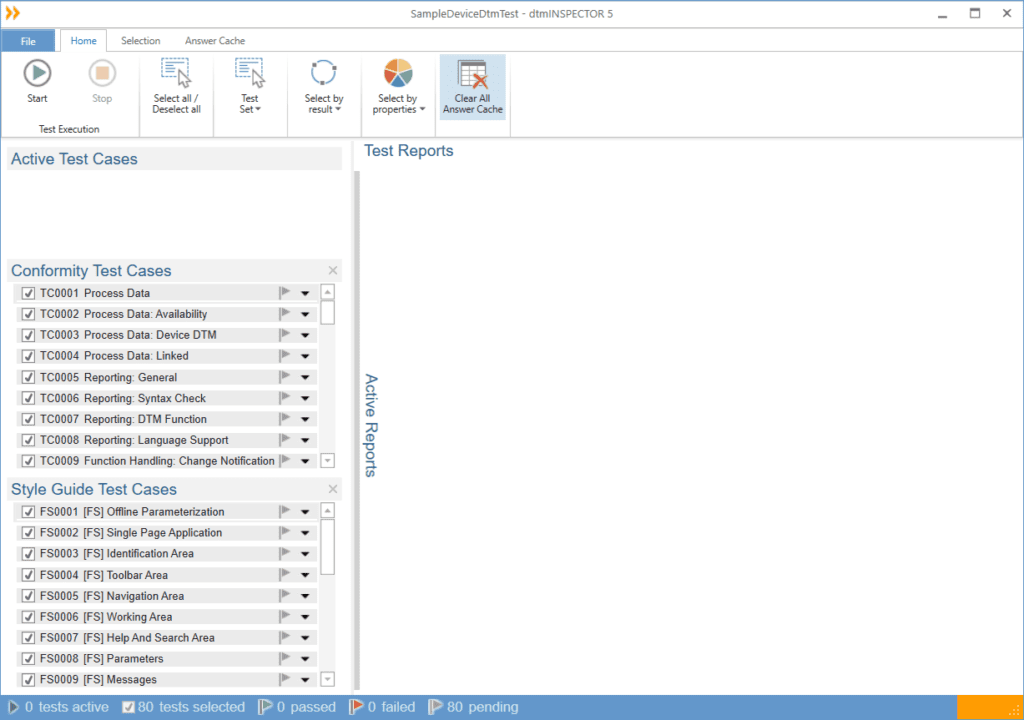

Figure 2: dtmINSPECTOR5 main window with all the Conformance and Style Guide Test Cases

Besides the necessary functionalities for certification, dtmINSPECTOR delivers all the properties to effectively ensure DTM development compliance. The tool’s scripting engine enables developers to write their own functional test cases for a device. In doing so, they can create a powerful test environment providing optimal support throughout the DTM development process.

The new test tool for FDT 3.0 is called dtmINSPECTOR5, which builds upon the test tool for FDT 2.0 known as dtmINSPECTOR4. For the independent test sites responsible for DTM certification, the upgrades with dtmINSPECTOR5 offer greater convenience and will help to reduce the time and effort required for testing vendor-supplied DTMs.

Because a significant portion of the business logic for DTMs from FDT 2.0 specifications has been retained in the FDT 3.0 standard, only minor changes have been made to the architecture of the dtmINSPECTOR software. Most of the FDT 2.0 test cases are ported into this new tool, with the necessary changes made to adapt them for FDT 3.0.

Making UI Style Guide compliance mandatory

The FDT 3.0 Industrial Internet of Things (IIoT) ecosystem development environment, intended to simplify the journey to innovative IIoT and Industry 4.0 solutions, includes an updated FDT 3.0 Style Guide empowering a standardized, responsive-by-design Web UI for new solutions developed by the supplier community. No other standard offers a more comprehensive, template-based approach for the industrial UI.

With the FDT 3.0 standard, DTM testing and certification has been broadened to include compliance with the FDT 3.0 DTM Style Guide. This requirement was not in effect with FDT 2.0, which allowed instrumentation suppliers to make their own decision regarding style guide compliance. FDT 3.0 DTMs must now pass both Conformance and Style Guide tests to receive certification.

The FDT 3.0 DTM Style Guide stipulates a uniform approach to the DTM user interface that employs a responsive design focused on mobilizing secure remote access independent of the device, system, browser, operating system, etc. The Style Guide describes elements of the automation interface in the HTML5 JavaScript world, so it is based on a state-of-the-art approach. The FDT 3.0 Web UI is suited to a new generation of workers who are digital natives and expect to use web-oriented technologies.

A critical aspect of the FDT 3.0 DTM Style Guide is ensuring a uniform UI with the same look and feel, presenting information in a consistent fashion across different vendors, devices and applications. This is especially important with new mobile solutions being deployed in industrial facilities. As such, compliance with NAMUR NE-107 recommendation is now required within the FDT 3.0 Style Guide. NAMUR NE-107 stipulates that plant operators need to view the process, including the status of the instrumentation, in a simple and uniform way—regardless of the source device—to support predictive maintenance strategies. DTMs are a crucial enabler for apps intended to view the health of field devices, and subsequently improve maintenance workflows.

Whereas developers did not receive the DTM Style Guide test tool as part of FDT 2.0 certification—this functionality was only available to the test center—the style guide tool has been embedded in the FDT 3.0 dtmINSPECTOR5 tool version. This enhancement reduces the burden on developers and provides them with additional test coverage before submitting their DTM for certification.

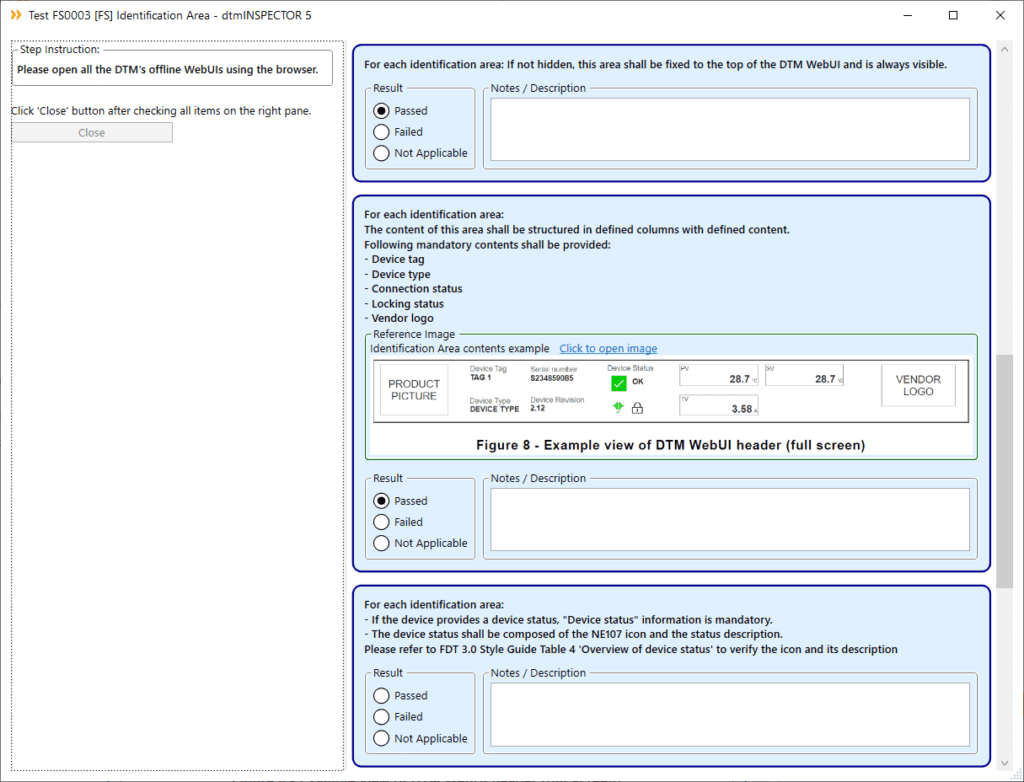

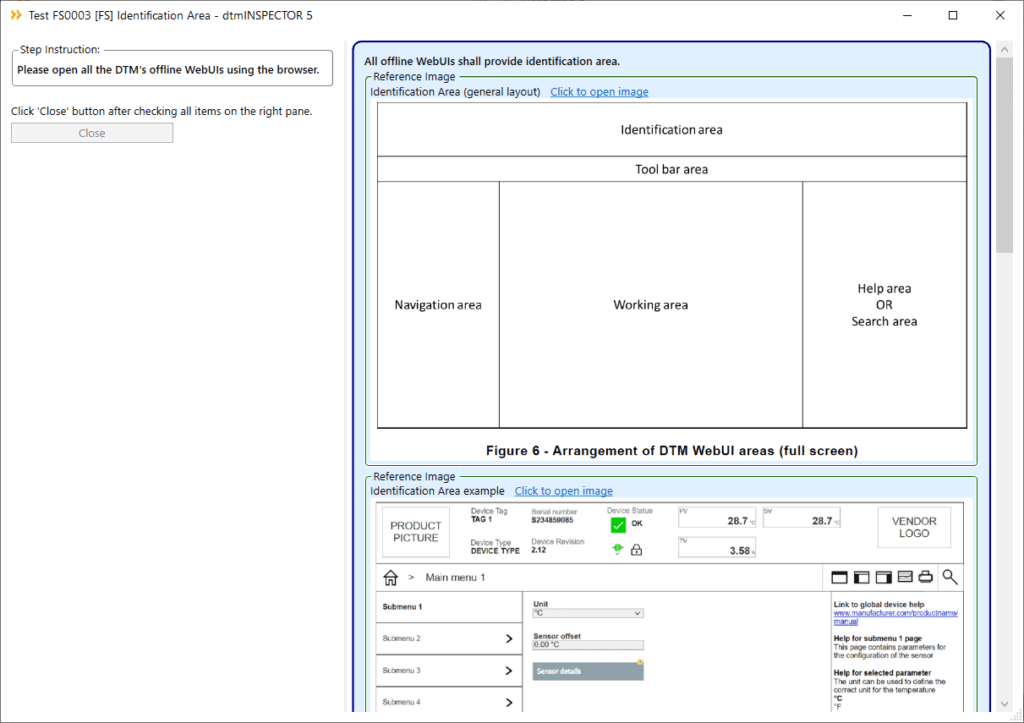

Figure 3: dtmINSPECTOR5 screenshot of one of the Style Guide test cases: FS0003_IdentificationArea. Left side pane provides user with the instruction about this test case. Right side pane provides all check items of this test case. Each check item is surrounded by a blue border. Some check items may include sample reference images for user. User needs to check (select option) each item to proceed with next tests.

Figure 4: dtmINSPECTOR5 screenshot from the same Style Guide test case FS0003_IdentificationArea. Because this test case contains several check items, user needs to use scrollbar to go through all check items. In this screenshot, you can see user has three options (Passed, Failed, Not Applicable) to select. User can also write down notes in the “Notes / Description” text box.

Strengthening the official certification process

Upon release of the FDT 3.0 standard, FDT Group instituted a mandatory certification process for all new FDT 3.0 DTMs entering the market. This development was spurred by requests from leading end user organizations such as NAMUR for greater consistency and interoperability across the industrial device installed base.

Within the FDT 3.0 environment, certified DTMs are built using platform-independent tools and therefore are interchangeable with cross-platform functionality. Vendors will now be required to declare the platform independence of their DTM as part of the certification process.

FDT Group has also fortified the security measures related to the FDT 3.0 DTM certification process. Once a DTM has met all the mandatory testing and compliance requirements, the certification files are compressed, digitally signed and submitted via a private channel to the FDT Group Certification Office. This procedure ensures the certification process isn’t spoofed or tampered with in any way.

Finally, FDT Group has established the FDThub for convenient storage and management of all certified DTMs. This repository, which can be hosted in the cloud or on premise, is the result of user-driven demand for a single location to find certified DTMs and updates. The FDThub leverages the workflow from independent test centers to the FDT Group certification office so that all certified DTMs are automatically uploaded to the repository and made readily available to the end user community. This solution eliminates work for the vendor and is a key benefit stemming from the mandatory DTM certification process.

Benefits to automation industry stakeholders

FDT is the most widely recognized and accepted data-centric integration standard for network and device information and asset management in the industrial market. As such, automation stakeholders expect ongoing improvements to the standard to enhance their user experience, security and performance outcomes.

FDT Group has taken important steps to improve the maturity of its testing procedures and strengthen the practices of accredited tests centers responsible for DTM certification. Recent upgrades to the organization’s multi-faceted DTM certification process will help to increase the confidence of end users in vendor solutions employing FDT technology.

The combination of the DTM Common Components tool kit, which has undergone rigorous testing to ensure compatibility with the FDT 3.0 standard and interoperability with the FDT Server Common Components, and the additional test coverage and certification processes provided by dtmINSPECTOR5, will result in a more robust and secure solution for the end user.

Industrial organizations will now benefit from optimized visualization across any mobile device, browser or host-based HMI utilized by the leading automation supplier platforms. They can employ a similar interface from device to device, which, in turn, will simplify navigation and ensure consistent notifications and warnings. All data and events will be presented in a standardized manner. This uniform approach will make training of engineers and technicians much easier while simplifying a wide range of operational tasks.

Thanks to the new FDThub repository, end users will no longer be required to search for certified DTMs for their application. The FDThub allows for automatic device discovery and notifications when new DTM updates are available, and vendors can manage their DTMs with user role access privileges.

Conclusion

FDT Group has served as a global standards association for more than 20 years. The organization has listened to automation suppliers and end users around the world to continuously evolve its technology and strengthen its DTM testing and certification procedures.

For more information about developer tools and certification, please visit https://www.fdtgroup.org/development.