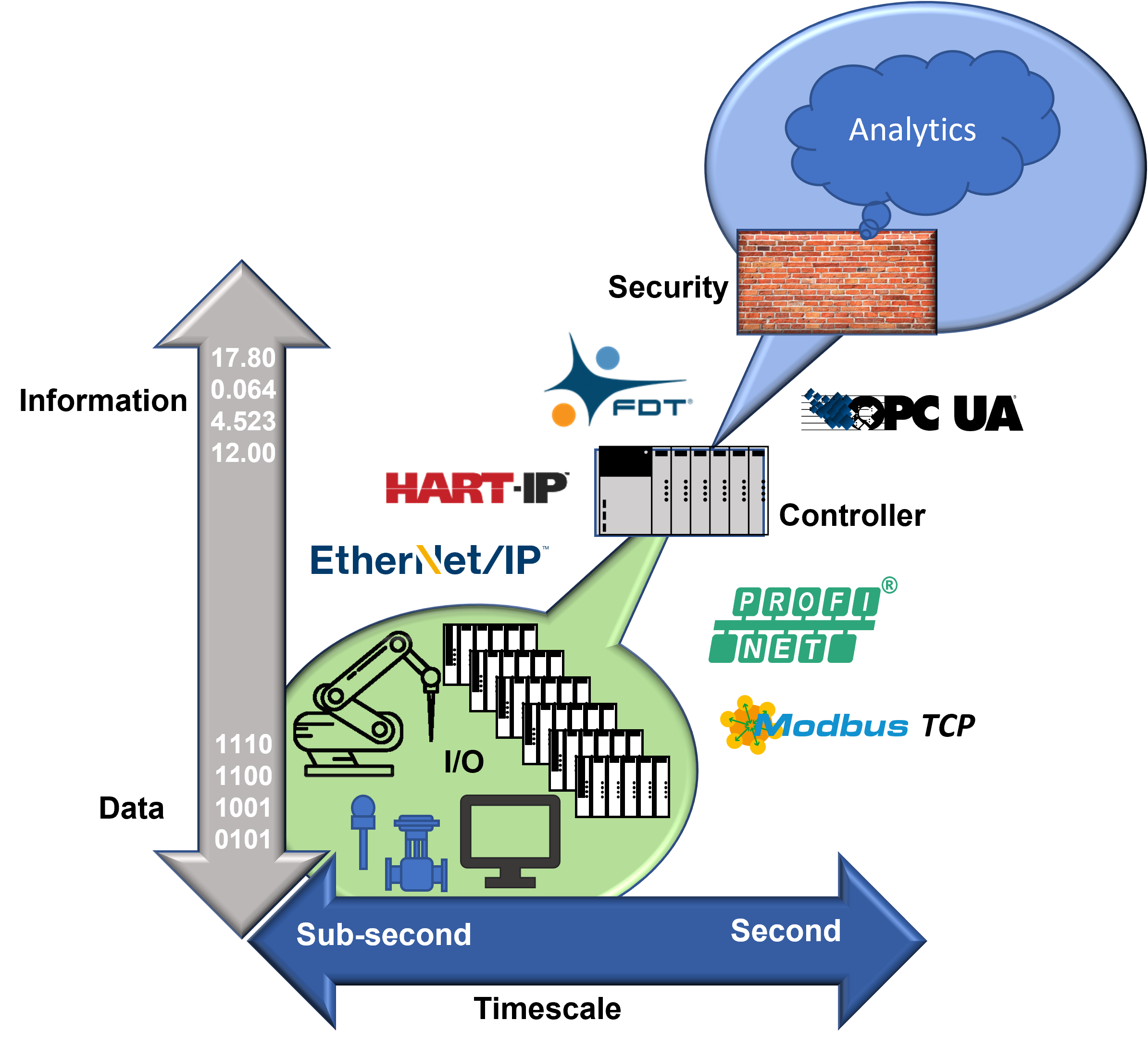

FDT/DTM’s Flexibility in Integrating Hybrid Applications with EtherNet/IP and Modbus TCP Protocols

Standardization for intelligent device management brings UI and data consistency for the enterprise

From Fragmentation to Unity: FDT/DTM Technology’s Role in Configuration

Unified Environment for Intelligent Device Management in Control Applications

Special Interview – What FDT/DTM Technology Means to VEGA, Sensors and the Industry

John Groom, CEO and Managing Director of VEGA Americas sat down with Steve Biegacki, FDT Managing Director, to discuss what FDT/DTM means to VEGA, sensors, and the industry.

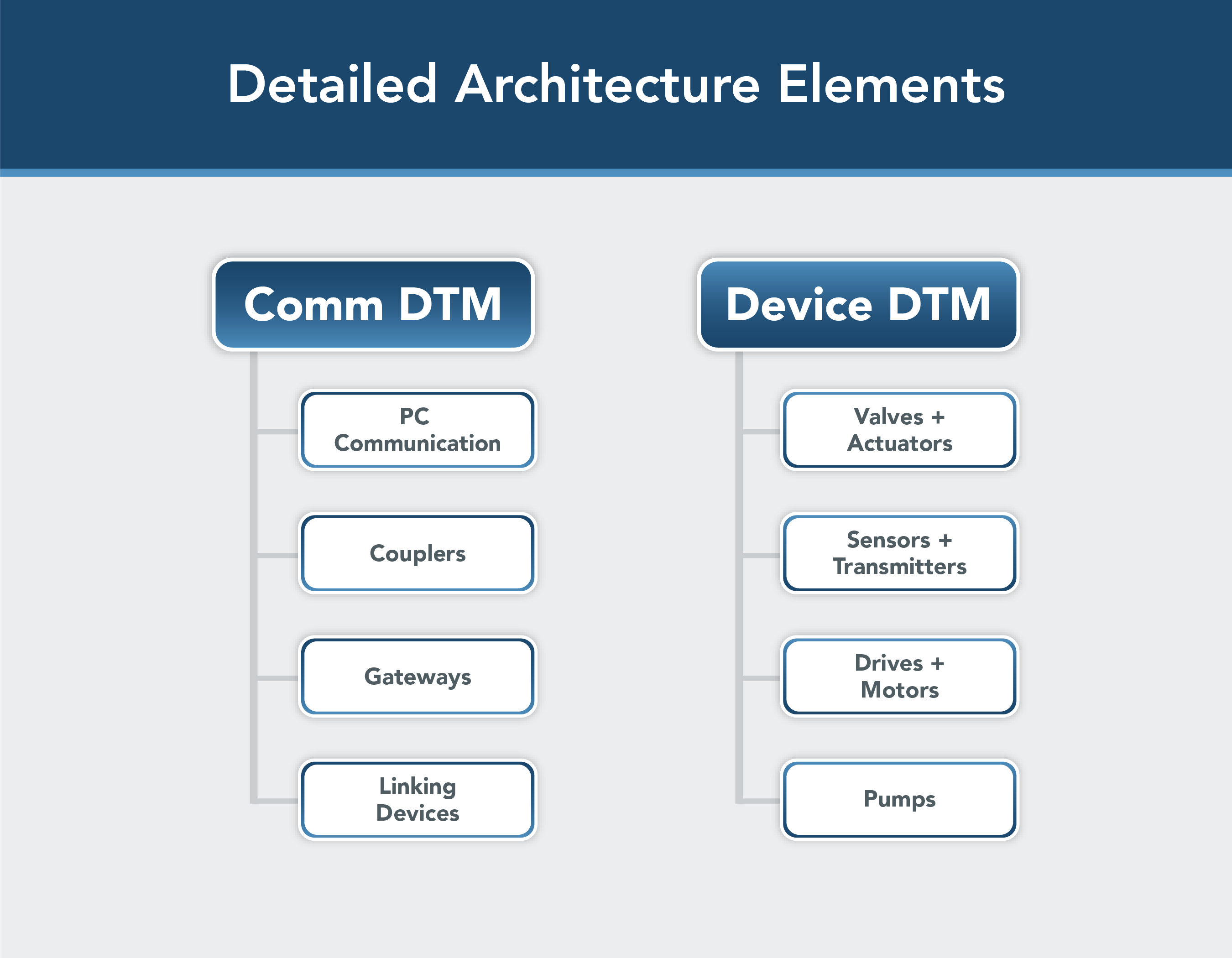

DTM is the Heart and Soul of IDM

The DTM enhances the circulatory system of control applications, opening the door to modernization

DTM Opens HART to Modernization

Solve industrial device management complexities by simplifying the process

M&M Software – FDT Service Provider Interview

Pingsheng Xu talks with Steve Biegacki about how they are helping the vendor community meet innovative manufacturing initiatives and preserve the legacy install base with FDT/DTM technology

Utthunga – FDT Service Provider Interview

Interview with Utthunga (FDT Service Provider) focuses on how they help system and device vendors solve device integration challenges using FDT/DTM.

Editorial: Unifying Control Systems for Industrial Automation Markets

Streamline operational lifecycle management for process, hybrid and discrete/machine builder applications

Can FDT/DTM Technology Work in Factory Automation and Hybrid Applications?

The great unifier for industrial engineering control environments

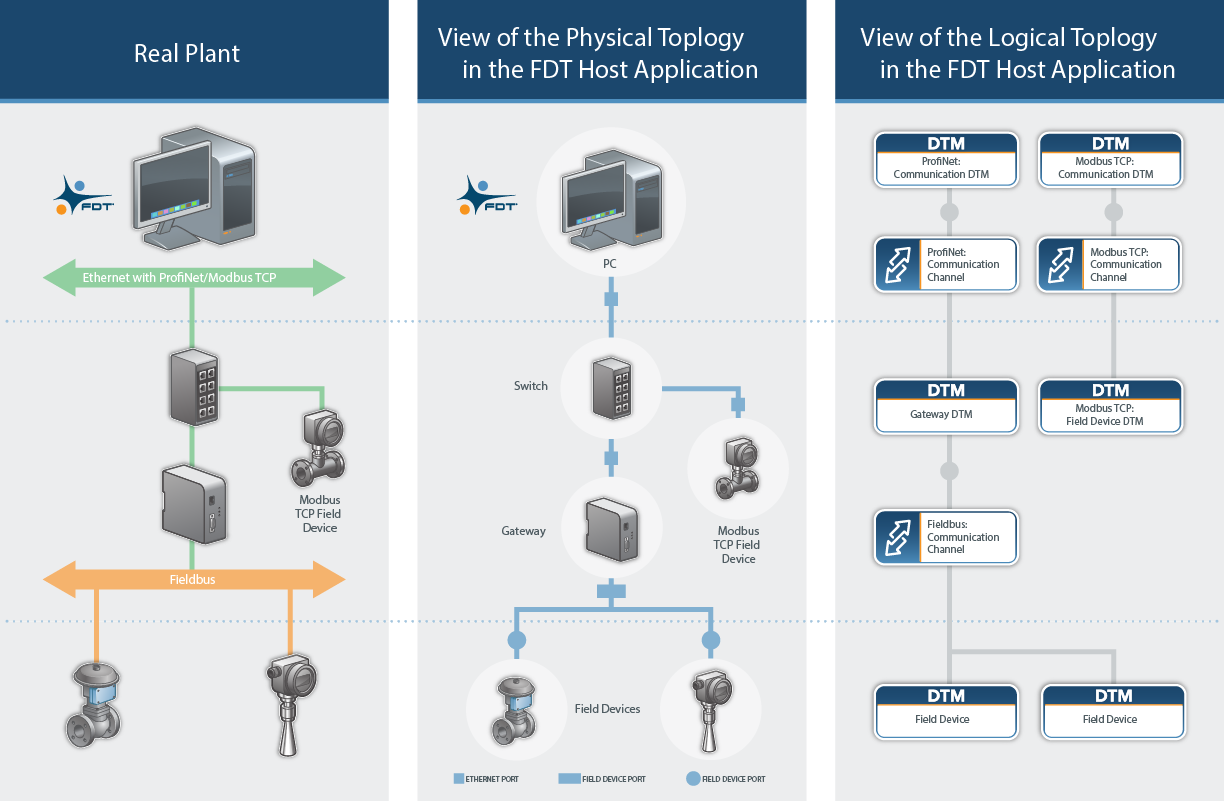

Unified Environment for Control System Integration

Common use of open standards lay the foundation for interoperability