Mistaken perception?

There is a common belief amongst the automation community that FDT/DTM (IEC 62453) technology is only applicable for process automation applications. This belief could be a consequence of the typical article, ad or video that is made for the promotion of this open standard.

Finding out answers

This article is to inform and raise awareness that a correct implementation of FDT technology can be effectively utilized in any industrial control automation environment, including factory automation and hybrid applications – plants that feature both factory and process automation applications. Whether the application deploys fieldbus networks, HART field devices, remote I/O systems, drives and motor starters, or sensor networks, it is likely that the manufacturer has a DTM (device driver) created for the devices it supplies.

One of the causes behind this mistaken perception could be the typical example shown in the available documentation or case examples of the FDT/DTM concept, which always features either a field device or a control valve.

There is a good reason for this approach – field transmitters and control valves are good examples of complex devices that benefit from a comprehensive asset management implementation, which enables plant operators to obtain large amounts of data from the field using a uniform and user-friendly interface.

The other cause may be due to the association of the use of FDT technology with device commissioning software applications (PACTware or fdtCONTAINER), which are offered by field device suppliers as freeware applications.

The great unifier

One of the use cases that limited the adoption of smart devices was that suppliers’ engineering tools had to use different integration software to gain access to the data available in the connected field devices. Major DCS suppliers could afford to include integrated asset management solutions into their plant-wide software systems that worked fluidly with their engineering software. However, smaller suppliers, especially third-party field device and interface technology suppliers, could not afford to support smart field devices in their less expensive, factory-oriented modular remote I/O systems.

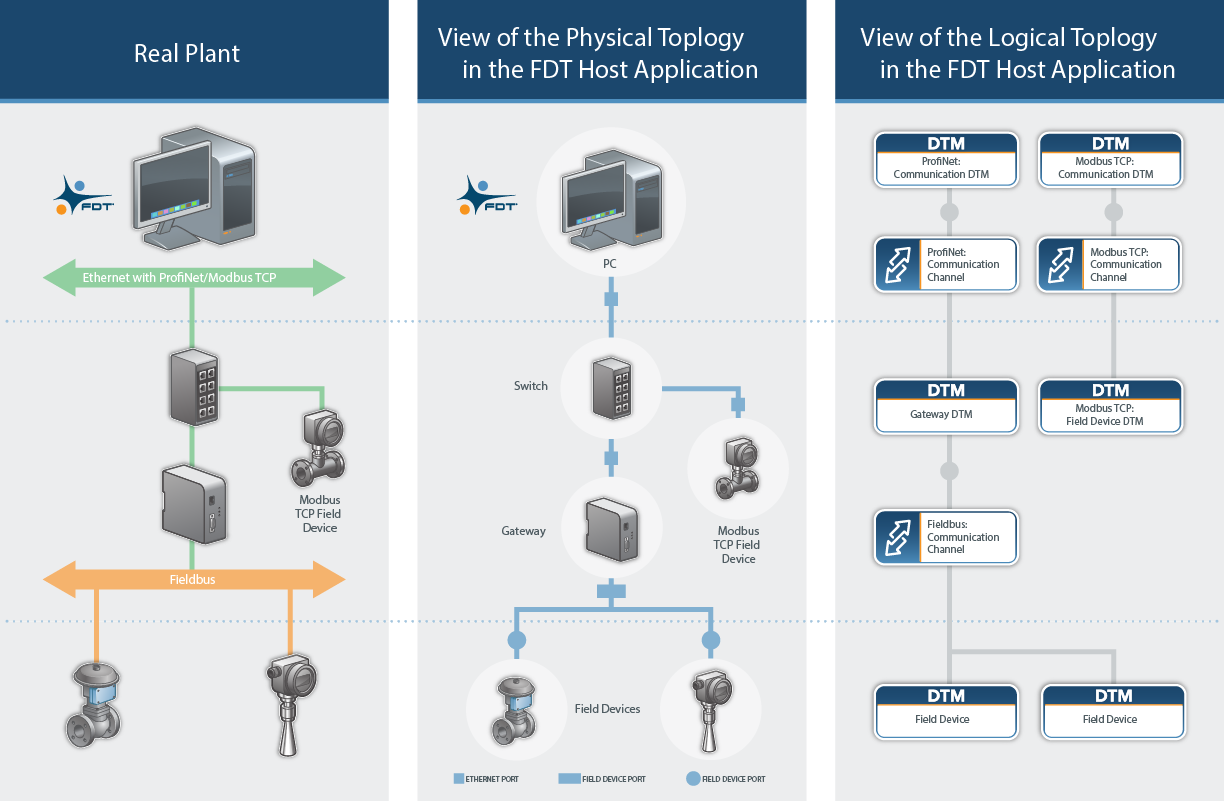

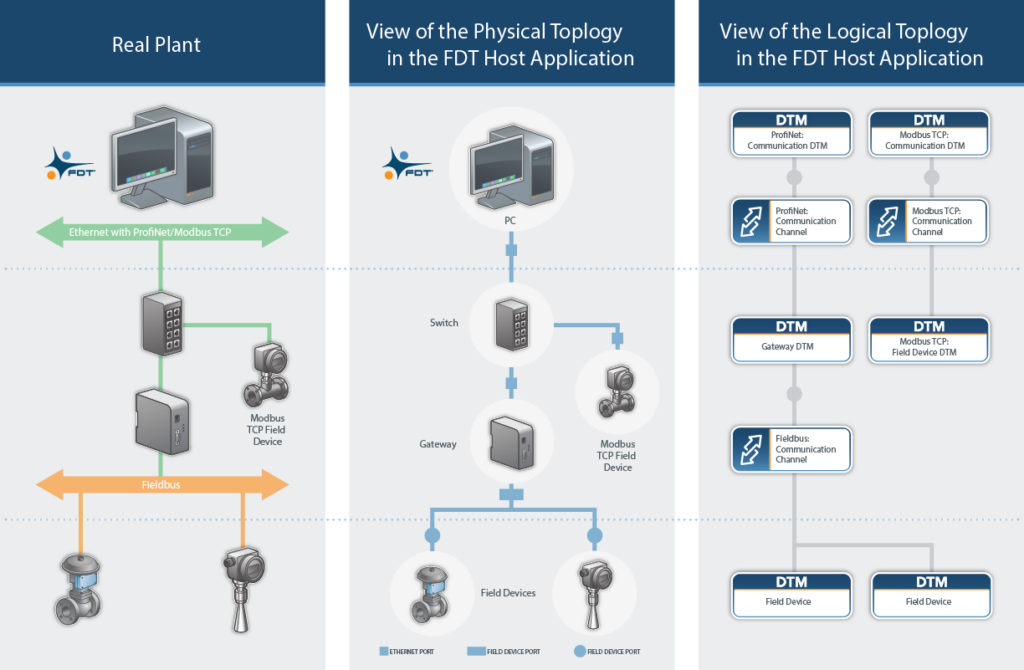

FDT technology has supported communication ‘nesting’ since specification version 1.2. Nested communication support enables DTMs to communicate with devices that use the same / or different communication protocols that are attached to different hardware levels. This ‘nesting’ feature harmonizes the topology and data structure providing a unified environment for device management.

FDT’s nesting communication feature, combined with the modularity framework application concept, allowed smaller suppliers to incorporate the FDT core application into their existing engineering software solutions.

Using the FDT framework, vendors can offer economically appealing compact modular RIO systems with HART support. Manufacturers, including: Phoenix Contact, WAGO, Beckhoff, Weidmuller, and Turck, now have I/O solutions that work as either low-cost remote I/O solutions for factory automation applications and by including integrated HART support that, when combined with intrinsically safe versions of key I/O modules, can be successfully employed in hybrid applications.

These applications of FDT/DTM technology take advantage of one of the most important features – applications are available either as a standalone configuration tool or as a modular middleware hardware integration tool that can be embedded into any engineering control application to a level where it becomes almost invisible to the operator.

A solution for nested communication applications

To clarify this point, let’s review some FDT/DTM basic concepts.

In FDT/DTM technology, there are three basic types of DTM files:

- Device DTMs – work in a similar way as hardware drivers and run in a FDT framework application.

- Gateway DTMs – work as device drivers but also provide protocol translation and media conversions for industrial communications gateways.

- Communication DTMs, also known as Comm DTMs, provide communication channels for devices connected through nested communication networks (any protocol).

Nested Communications within an FDT Host Application (DCS, PLC, Configuration Tool, Asset Management Application, etc.

Nested communications enable suppliers to offer complete I/O subsystems that can be delivered with head stations compatible with whatever protocol that may be required by the end user, a family of components such as power supplies and I/O modules, and a user-friendly FDT-based integrated asset configuration management solution. This solution avoids powered backplanes with hot-swapped I/O modules and redundancy schemes for cost reduction because these features are not usually required in machine control applications.

Typical application examples

Let’s analyze the following application examples of FDT technology in hybrid and factory applications:

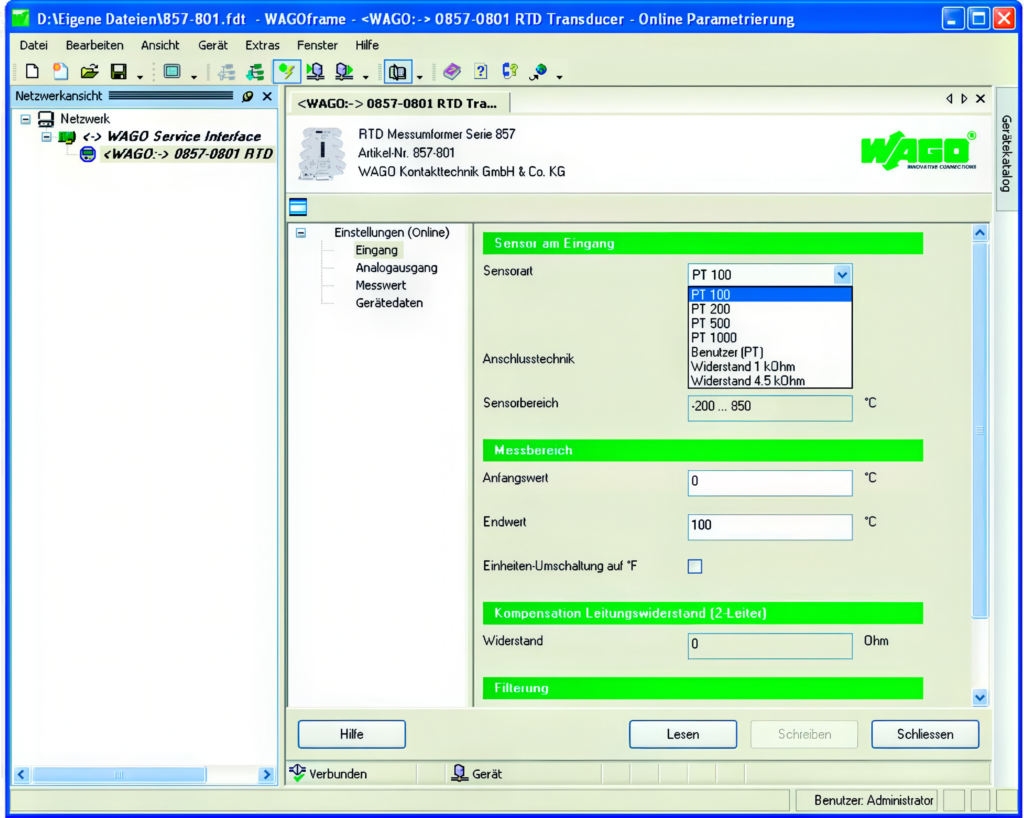

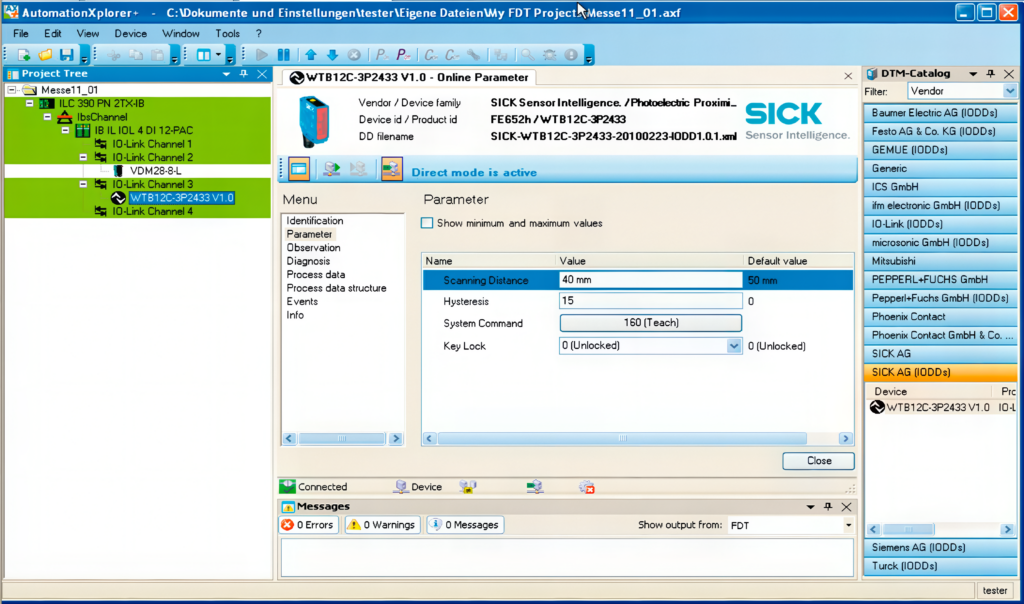

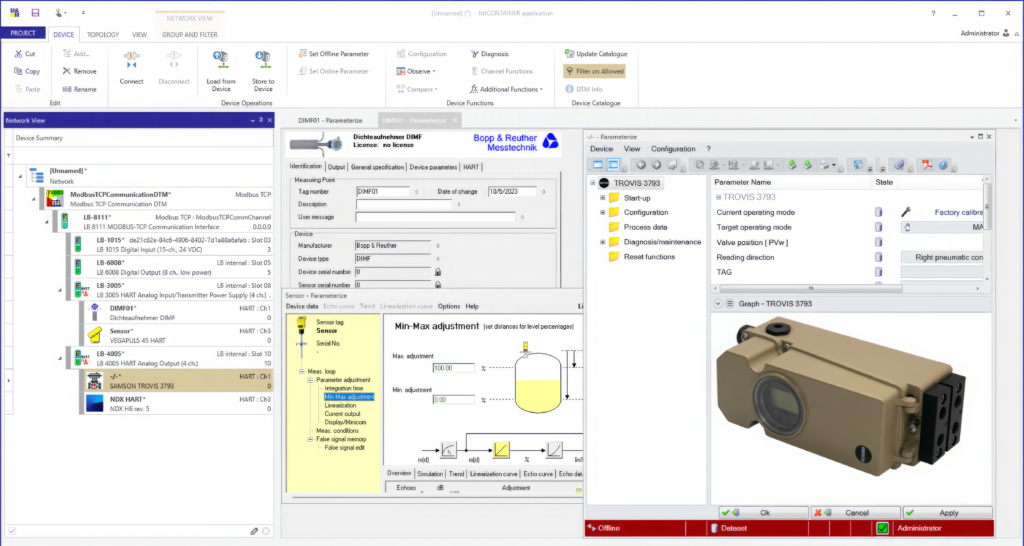

Use of FDT technology in Remote IO systems with nested communication network support (HART through Modbus TCP)

Remote I/O subsystems are particularly adequate to use the modular approach that the FDT/DTM concept provides.

A typical remote I/O implementation of FDT technology will look like this:

- A Comm DTM is used for the communication of the RIO system to the control system backbone network.

- A Gateway DTM is used for the integration of the RIO system head station. This modular DTM allows end users to replicate the I/O module structure implemented in the application.

- Device DTMs are used to support the smart devices connected to the corresponding RIO modules.

The most common implementation of FDT technology in RIO systems would be HART-enabled I/O modules in combination with HART-enabled field devices. In this case, the I/O modules can send information about any device connected to them, whether they are smart or traditional devices.

This arrangement provides access to all features of a smart device with its specific Device DTM running in the FDT framework application, whether running as a standalone application or as an integrated engineering application. At the same time, it provides easy access to basic diagnostics for simple non-smart field devices, like short circuits and lead breakage information from connected DI and DO discrete devices. Therefore, this is a built-in method to bring intelligence to non-smart devices.

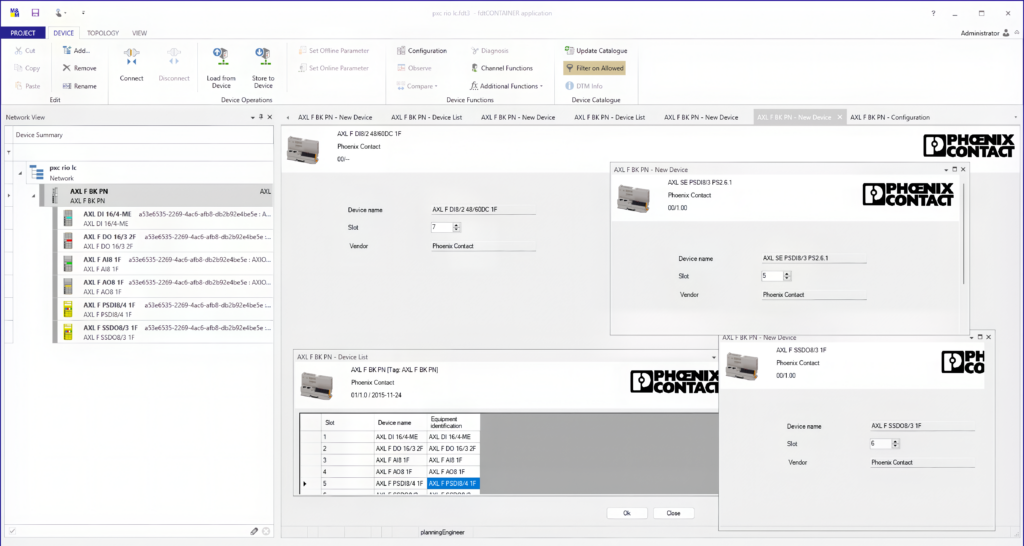

An integration solution for machine builders

Using compact modular RIO systems provides a solution well-suited for machine builders. This kind of manufacturer can design a machine with a common I/O configuration and the choice of the most adequate communication head station. If the machine is connected, to a control system compatible with FDT technology, its integration becomes trivial.

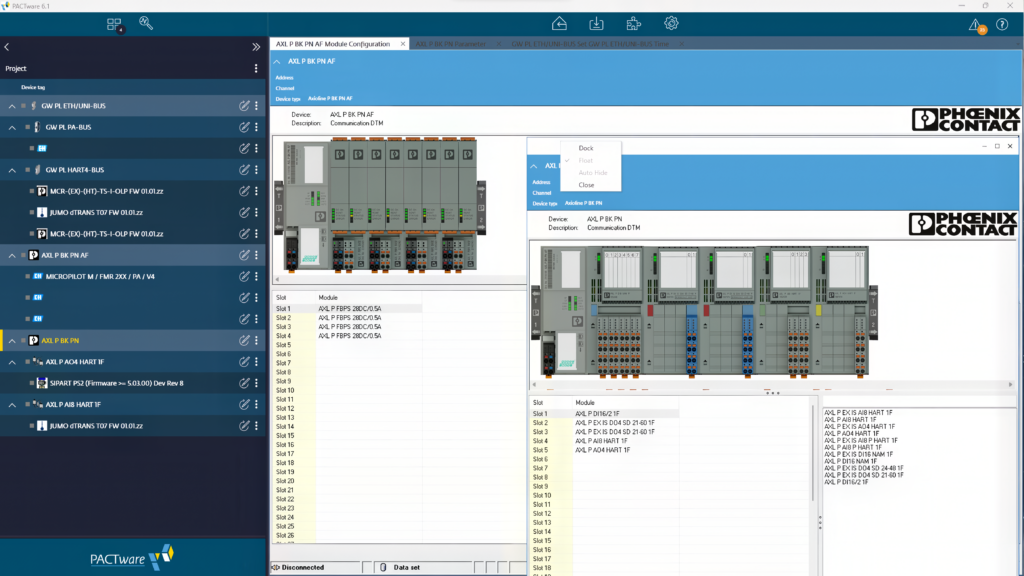

Low-cost Phoenix Contact RIO system for machine control applications featuring DI, DO, AI and AO modules.

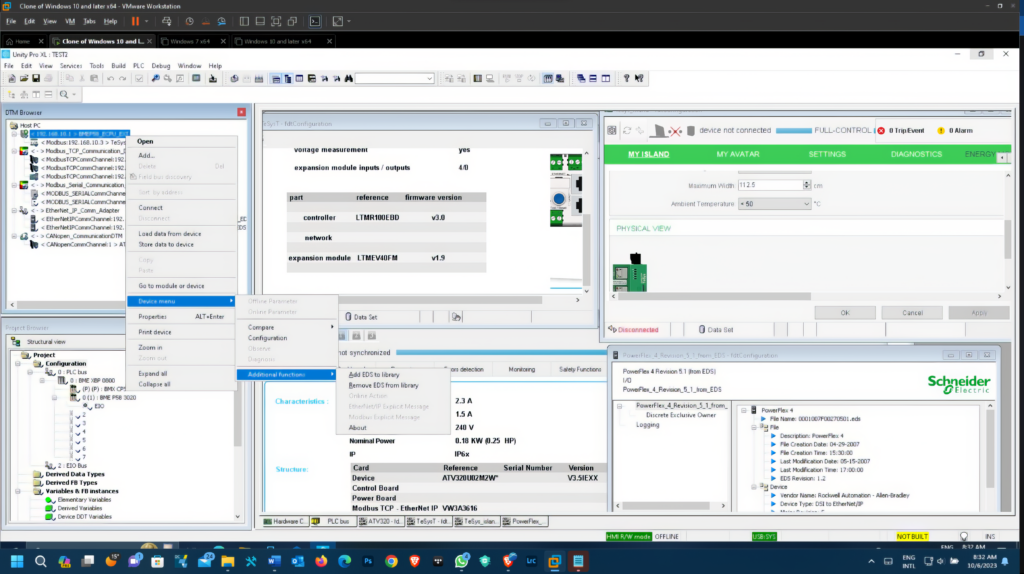

Another non-process-related application of FDT technology consists of the integration of complex actuators such as speed drives, control drives, and motor commands.

For this type of application, there are not as many DTMs available. Most of the available solutions come from the Schneider Electric product line. Schneider’s approach to these kinds of applications has a secret feature – they have incorporated an Interpreter DTM that converts EDS (Electronic Data Sheet) files to DTMs included in their Generic DTM for Ethernet/IP Adapter Devices and their Modular Generic DTM for modular EtherNet/IP Adapter Devices.

EDS import tool using the EDS to DTM functionality.

This tool offers end users the ability to import any EDS file corresponding to any EtherNet/IP device and present the EDS as a Generic DTM. Therefore, in addition to Schneider’s motor control devices with native DTMs, you can use Rockwell Automation’s ample line of EtherNet/IP devices whose EDS files can be accessed through the FDT framework.

Embedding FDT technology into control engineering systems

Perhaps the best example of a control software platform based on an FDT core solution is Schneider Electric’s EcoStruxure platform. In this FDT/DTM implementation, the FDT core works as the hardware configuration component of the engineering tool.

Its behavior clearly resembles how smaller platforms like PACTware work. After starting the main software application, the embedded FDT environment scans the server, workstation, or VM where it is installed and looks for any newly installed DTM. Afterward, the new DTM is seamlessly integrated into the DTM catalog.

A Unity Pro FDT configuration using Ethernet IP, Modbus TCP, Profibus DP and PA, Hart and Modbus serial Comm DTMS

When the EcoStruxure PLC programming solution is running, after the CPU and I/O options have been selected, the integrated framework works as the host for all the available DTMs.

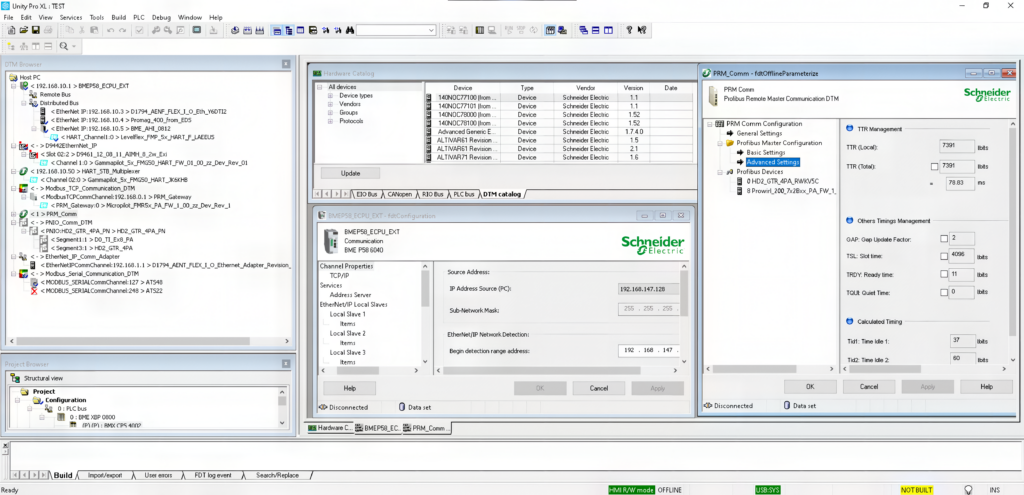

One single solution for all fieldbus protocols

Most third-party fieldbus interface solutions designed for specific PLCs require the use of a fieldbus specific software tool for its configuration. This software works by mapping the I/O information from the field devices that the controller requires to create the I/O image map in the controller’s memory. The controller does not require the additional data that a smart field device can generate.

If the control system’s installation employs more than one fieldbus protocol, a different configuration tool is necessary.

The use of an integrated FDT framework greatly simplifies these types of applications by using a single configuration utility for the integration of different communication protocols into the control system.

Support for any new protocol is enabled by the corresponding Comm DTM, which becomes part of the hardware catalog of the PLC programming platform. This approach allows the inner working features of the protocol to be hidden from the user interface.

The user can add any device supported by any available Comm DTMs installed in the system. The FDT framework works like an abstraction layer, enabling the system to have seamless access to connected devices. Each device DTM becomes available for access through the corresponding Comm DTM. When connecting RIO systems or field buses, a Gateway DTM must be installed below the Comm DTM in the topology. This allows RIO I/O modules or specific fieldbus devices to be added to the system by connecting them to the right Gateway DTMs. The main advantages are that all fieldbus interfaces are hidden by the framework application from the user, working as an abstraction layer for the fieldbus protocols used for connecting smart devices.

Using this approach, a FDT compliant controller may be equipped with different Gateway and Comm DTMs for each of the protocols required.

Let’s see a couple of examples:

Phoenix Contact Profinet RIO using Hart gateways, Axioline P RIO modules and a Profibus PA to Profinet proxy.

- Using an Axioline P Remote I/O, in combination with compatible HART modular Gateways and a redundant Profibus to Profinet Proxy, it is possible to connect a controller with DI and DO signals, HART Devices and Profibus PA field devices.

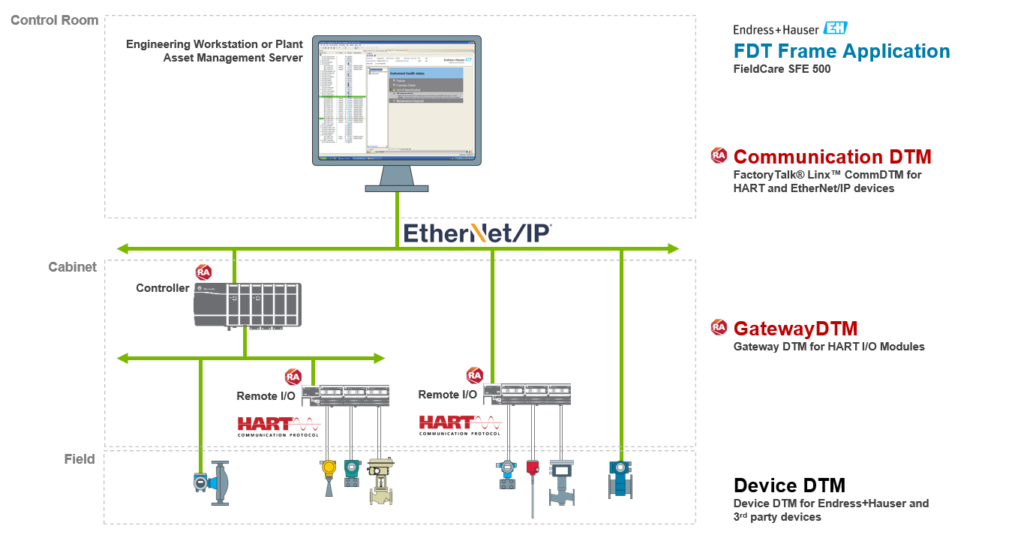

- If you are a Rockwell Automation user, you may be working with the FactoryTalk software suite. This software package allows the integration of all kinds of devices, I/O system, and controllers into a companywide implementation of cloud-based applications, IIoT solutions and data processing services, such as Microsoft Azure or ThingWorx. The hidden ingredient in this plant wide solution is a piece of software known as the FactoryTalk Linx CommDTM.

Functional scheme of the FactoryTalk Linx CommDTM

As an example, in the FactoryTalk Suite, the FactoryTalk Linx CommDTM enables the communication of any device DTM connected to the system through an EtherNet/IP, ControlNet, or a DeviceNet network.

The FactoryTalk Linx CommDTM is the key part of the whole FactoryTalk architecture. It employs an embedded FDT framework application known as FactoryTalk AssetCentre that allows the system to perform asset management operations such as remote commissioning, configuration, parameterization, and diagnostics of any CIP-enabled device connected to the system.

In FactoryTalk, this functionality is available to any CIP-enabled device connected, if a DTM is available, for that device. It is not limited to process field devices.

In fact, one of the subsystems that benefit the most from the use of FDT technology in the Rockwell product portfolio is the remote I/O subsystem.

Hybrid plants

In hybrid plants, there may be a primary area dedicated to, for example, beverage production, which sometimes may require flammable oils for flavoring or alcohol-based products from the production of spirits. These processes involve hazardous areas and usually require batch process control. The typical application solution would feature either HART field devices, Profibus PA field devices, or EtherNet/IP devices.

Schneider Electric’s EcoStruxure platform supports both native Profibus Remote Master (PRM) and third-party Profibus masters that allow the system Profibus support.

Both native and third-party RIO systems can be configured using the corresponding DTMs and can also work as HART gateways when equipped with AI and AO cards with integrated HART modems.

These systems are available with either Profibus DP, EtherNet/IP, or Modbus TCP support. DI and DO cards that include lead breakage and short circuit detection for simple binary sensors can provide additional functionality.

RIO systems typically equipped with intrinsically safe IO cards include HART support.

All these devices can be integrated using the embedded FDT framework application into the PLC configuration and programming software.

Integration of devices without original FDT support with products from third party suppliers

One of the key features that FDT technology offers is openness. Even if a manufacturer does not have a DTM for their devices, there are viable alternatives.

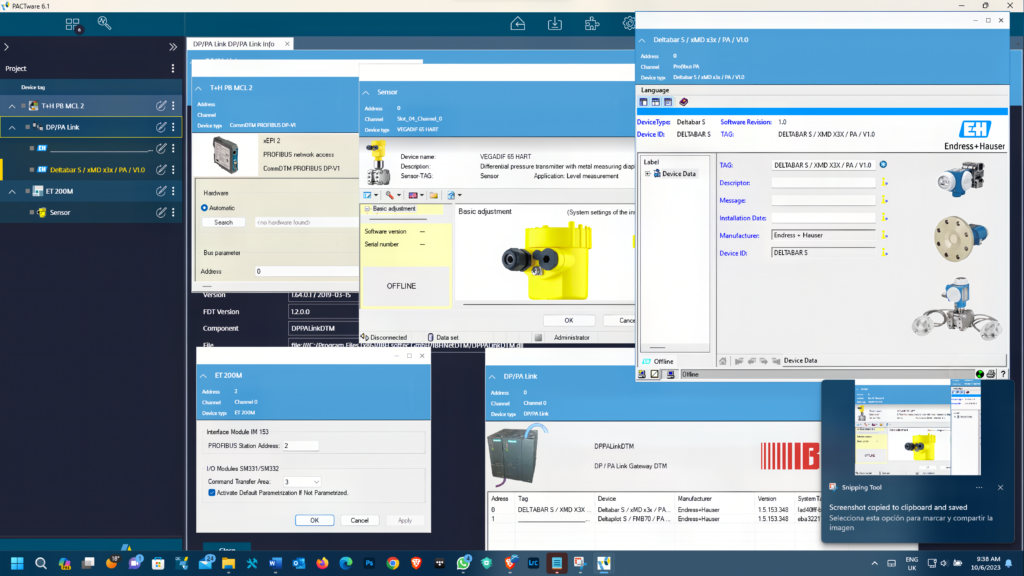

Software developers have created third-party DTMs for popular hardware, like the third-party DTMs created to enable asset management of devices such as Siemens DP/PA Links and ET-200 remote I/O systems. With these Gateway DTMs, you can use an FDT framework in a Siemens-based control system and unite for the typical asset management tasks required by both Profibus PA and HART smart transmitters.

Third party DTMs used for Siemens DP/PA link and ET-200 M RIO system.

Perhaps the user will not have access to the complete features of a certain device by using these Generic/Universal DTMs, but for most of the applications, the range of functionality achieved is good enough. And the benefits of a user-friendly interface are notable.

A future proof solution ready for OPC-UA and the NOA concept

Since specification version 2.0, FDT offers support for the OPC UA standard. FDT technology uses the OPC UA for the FDT Device Information Model, implemented in an OPC UA Server, allowing device information corresponding to any DTM installed and running on any FDT framework application to be mapped and accessible to higher-level applications.

Using OPC UA technology makes all the data supplied by the field infrastructure available to any OPC UA client application that may require that information.

Lastly, FDT technology allows a simple path for the implementation of the Namur Open Architecture (NOA) concept, which consists of a second channel of communication between the field level and the upper levels of the traditional automation hierarchy, unlocking access to additional field data for the following purposes:

- Monitoring of field devices, process analyzers, electrotechnical equipment, etc.

- Plant or fleet management of mechanical equipment

- Accessing data and/or implementing additional measurements for process optimization

The NOA concept objective is to provide an additional Digital Operational Infrastructure (DOI) for monitoring and optimization (M+O) purposes for increased reliability, easier maintenance, improved energy efficiency, and personnel safety.