The quest to increase productivity never ends for manufacturers. In the current economy, industry leaders are often determined by their ability to operate more efficiently, with higher quality, and at a lower cost than their competitors.

The first industrial revolution occurred in the late 1700s (factories), the second during the early 20th century (automobiles) and the third after World War II (computers). As a result of these revolutions, products are manufactured faster and with higher consistency, and have greater value to customers.

The industrial revolution now underway, commonly referred to as Industry 4.0, is powered by advancements that include smart manufacturing, advanced analytics and the Industrial Internet of Things (IIoT).

With networked production, interconnections, data and information exchange across the industrial enterprise will increase, thus making integration and communication more important. This is the driving force for FDT® technology, which provides a single, open, interoperable and standardized interface for industrial networks – extended to meet today’s growing worker mobility requirements.

FDT Roots in Industrial History

Figure 1: FDT Group’s goal is to ensure a “timeless” technology moving into the next generation of solutions to empower the intelligent enterprise.

Industrial organizations of all sizes are adopting modern automation solutions at an accelerating rate, but there is so much more opportunity yet to come as more and more organizations invest. This is a huge opportunity to address the barriers of integration and interoperability to bring companies into the future.

The history of FDT technology is one of advancement and innovation, as it has kept pace with the changing requirements of industrial automation, and the diverse needs of suppliers, end users and other stakeholders.

The FDT Group’s roots date back to the late 1990s, when the organization was established as an informal association by a number of leading automation firms to oversee FDT technology. The goal was to develop a single, open field device tool that would standardize the host interface with the device for seamless integration and complete interoperability regardless of the protocol(s) in use, providing open access to device intelligence. Support by global manufacturers both large and small came with the realization that FDT would be a key integration standard for the automation industry moving forward.

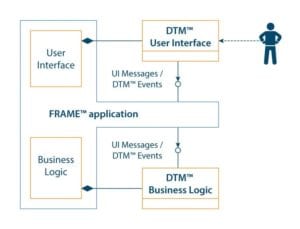

Figure 2: The key components of the original FDT Version 1.2 specification were a Device Type Manager (DTM) and FRAME application.

In May 2001, the first FDT standard was released to the marketplace as Version 1.2. The specification used COM and ActiveX as its base technologies. Its key components consisted of a Device Type Manager™ (DTM™) and a FRAME™ application. Within the FDT ecosystem, device manufacturers provide DTM software for their products, and the FRAME, embedded in control systems or standalone device management tools, communicates and reads those DTMs regardless of the protocol for each device.

With a growing number of FDT members, it was decided to formally organize the group as a legal independent entity. The FDT Group was officially founded in September 2005 as an International Not-For-Profit Association (AISBL). Shortly thereafter, the FDT standard became internationally recognized as IEC 62453, as well as the North American standard ISA 103 and China GB/T 29618.

FDT technology was developed for the purpose of advancing integration in the digital world of automation. Over time, it has become the de-facto standard in this market segment with tens of millions of DTMs installed in field instrumentation and tens of thousands of FRAMES deployed for integration, lifecycle management and information management.

Evolution of the Standard

Recent decades in the automation industry have seen fierce competition amongst major vendors, with the various standards organizations they support. But no matter if the technology was fieldbus, wireless, Ethernet or other implementations, end users have always sought consistency, standardization, interoperability and integration while ensuring minimal risk.

FDT is the only open, scalable, secure and interoperable architecture for the modern industrial environment, whether it is process, hybrid or discrete automation. The technology provides a vendor-neutral software interface for integrating assets and delivering access to device intelligence. This includes a common environment for utilizing intelligent devices’ most sophisticated features.

Industrial firms around the world have found FDT simplifies device/system assimilation at all phases of the plant lifecycle. The technology enables interoperability of device information in facilities with multiple or hybrid communication networks to improve reliability and lower costs – all made possible by harnessing the valuable data held in these intelligent assets.

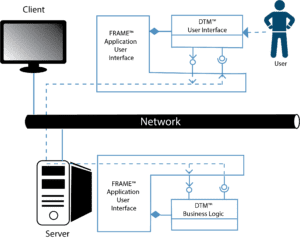

Figure 3: FDT 2.0 provides a client-server architecture, which allows separation of the DTM user interface (UI) and the DTM business logic.

In 2012, the FDT Group announced the advancement of its original standard to meet the needs of the new era of automation, supporting the lifecycle of tomorrow’s adaptive manufacturing assets. Developed to leverage WPF, as well as Microsoft .NET technology, the FDT 2.0 specification supports an enhanced user interface (UI) with enhanced graphical representations of device functionality. It maintains proven FDT heritage including numerous performance improvements. The technology provides backward compatibility with the existing FDT installed base, eliminating “rip and replace” scenarios when utilizing different generations of field equipment, and allowing new and existing software to coexist.

FDT 2.0 supports a client-server architecture, which allows separation of the DTM UI and Business Logic (BL). It also supports an OPC Unified Architecture (UA) companion specification in relation to the client-server approach. Any OPC UA Client can be authenticated and approved to access the FDT architecture.

FDT 2.0 also defines robust security capabilities with embedded certificates in DTMs and a host of user role enhancements. DTMs based on the current specification are digitally signed, providing tamper-proof software delivery and non-repudiation. Granular DTM security with enhanced user rights is added to the security settings.

Finally, “Common Components” providing a comprehensive development environment added to the deliverables with the release of FDT 2.0. These powerful, easy-to-use tools for developers saves time and money for FRAME and DTM development, assuring implementation of specification conformance for plug-and-play interoperability. They work along-side the dtmINSPECTOR for testing and certification of DTMs and improve ease of maintenance. Common Components allow developers to focus on the custom design features of their FDT-enabled solutions that distinguish their products from others, ensuring product quality with faster execution time to market. The tools will remain an important element to future revisions of the specification as the technology evolves.

To expand upon the rich features offered in FDT 2.0, FDT Group recently released the FDT 2.1 specification that focused on key technological enhancements along the migration path for the future. The updated specification provides expanded distributed architecture support, as well as improvements for ease of use with intelligent devices by handling larger volumes of structured data, additional security capabilities to protect against malware, increased communication performance and enhancements for mixed topology environments.

FDT 2.1 sets the stage for moving into FDT IIoT initiatives of enabled systems supporting a connected enterprise through creation of a single system infrastructure that standardizes the connection of disparate automation assets. Due to the Common Component approach introduced in 2.0, adopting 2.1 functionality require substantially less effort for vendors.

Enabling the Industrial Internet of Things

With the introduction of the IIoT, industrial automation is once again undergoing a tremendous change. This is made possible, in part, by recent innovations in technology that allow interconnection on a wider scale. However, there remains a need for standardized and open solutions to ensure today’s powerful automation assets can communicate and work together as required by the industry.

FDT Group’s goal is to ensure a “timeless” technology moving into the next generation of solutions to empower the intelligent enterprise.

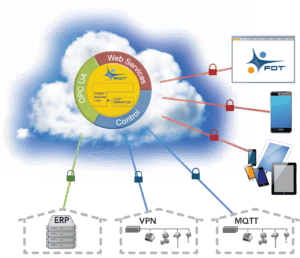

Figure 4: The FDT IIoT solution is built surrounding a core FDT Server, which serves as a broker enabling a wide range of client/server interactions.

Just as previous iterations of technology responded to needs of industry at the time, the FDT open architecture continues to be adaptive and broker new, advanced functionality and features. Recent enhancements respond to the new era of automation, with the FDT ecosystem evolving to incorporate modern web-based and mobile applications.

To strengthen its support for IIoT and Industry 4.0, and leverage its Version 2.1 technology enhancements, FDT Group is finalizing development of its new FDT IIoT Server™ (FITS™) architecture. Using Microsoft .NET technology, FITS is specifically designed to support implementations for client/server, multi-user distributed architectures enabling mobility, cloud, and fog accessibility enterprise-wide. The solution features robust layered security, leveraging vetted industry standards, and utilizes transport layer security (TLS) to establish a hardened shell and encrypt all communications throughout the architecture. Optionally, it can authorize devices that connect to the FDT Server. User-based security is employed to determine the user’s role and rights within the application.

The emerging FITS specification is planned to deploy in late 2018 with a complete development solution to advance compliant products to market, including servers and DTMs.

FDT Group and its members specifically are designing FITS to allow for complete interoperability across both current and emerging standards, supporting the convergence of information technology (IT) and operational technology (OT). Users can switch standard protocols for any level of network backbone. The enhanced architecture is scalable and modular to suit the needs of a single manufacturing facility, segments of a facility, or an entire industrial enterprise.

The FDT IIoT solution will be built surrounding a core FDT Server, which serves as a broker enabling a wide range of client/server interactions, whereby communication between these key components is standardized for its’ Control, OPC UA and Web Services interfaces. The Control element of the architecture establishes the “nested” communication to field devices included in mixed protocol architecture. This interface enables access to a wide range of field devices by “tunneling” through the network hierarchies.

Additionally, the OPC UA interface allows an OPC UA Client to retrieve information from any device connected anywhere in the plant. Thanks to the FDT OPC UA model, information for the OPC UA Client is independent of both the device manufacturer and the fieldbus to which the device is connected. An application for an OPC UA Client could be an asset management system that identifies the equipment topology, the attached devices, and related data (e.g., device type, manufacturer, serial number) through the FDT Server.

To advance the standard into mobile applications, the FITS architecture will introduce a Web Services interface, which boasts operating system (OS) agnostic support for standard browsers, and mobility standardization for the development of fit-for-purpose apps for easy maintenance efforts. The FDT Server provides an Application Programming Interface (API) to the Web Services portal authorizing clients such as a desktop or apps for mobile access to new DTMs employing HTML5 and Java Script. This standardized mobile access approach will enable any mobile device authenticated to access the server to have full access to the topology with tunneling capability to manage FITS-based DTM devices on any network.

For end users in the process, hybrid and factory automation markets, the FITS architecture will empower them with open solutions that remain modular, flexible, and scalable to support today’s installed base while advancing to adapt as the industry demands – thus streamlining the evolving ecosystem exchange of the future.

Mobilizing Today’s Workforce

Just as mobile devices are transforming the way consumers communicate, connect, shop, bank and work, mobility solutions are dramatically changing the landscape of manufacturing plants. With visibility, information and control literally in workers’ hands, plant processes and productivity are transformed. In Spring 2017, the FDT Group formed a project group for investigating the use of mobile devices. The objective was to drive real-time, data-driven analytics using web browsers and apps through an FDT standard interface via mobile devices. This technology development will help optimize industrial organizations and their maintenance departments by enabling cloud-based enterprise data access, robust device diagnostics, mobility applications, and the use of augmented reality in asset management and predictive maintenance programs. Here, too, the manufacturer- and fieldbus-independent model of FDT, along with cross-field communication, offers important advantages. This approach allows connection from the mobile device to the field device, even if the field device has no wireless connection, but is connected to wired networks. Users will benefit from much simpler device management through standardized apps instead of a variety of vendor-specific apps allowing seamless communication in a consistent manner with the various field devices.

Figure 5: FDT Server brokers new web services portal standardizing the interface via Apps for authenticated browsers, mobile and augmented reality maintenance tools.

Beyond cloud services with mobile applications, the use of augmented reality via a holographic human-machine Interface (HMI) and Microsoft’s HoloLens computing device will further address critical lifecycle management issues. Technicians will be able to view real-time data and analytics using hands-free operation, visualizing status and live data for each sensor location. The modular and scalable FITS solution is squarely focused on applications where worker mobility is needed. This could include the food & beverage and pharmaceutical industries, for example, where companies are under pressure to upgrade their automation equipment to better monitor product quality and standards compliance. Furthermore, FITS is well suited for Greenfield environments where monitoring of key performance indicators (KPIs) and optimal control of process operations is critical, as well as Brownfield applications where a part of the plant or facility requiring mobility solutions can be upgraded with a FITS architecture.

Conclusion

From the beginning, FDT has set the stage for open, standardized integration for bi-lateral communication and access to asset analytics across the enterprise. Today, the standard has become the heartbeat of any architecture, widely adopted and in use around the globe as trends move plants and factories towards connected manufacturing throughout the automation verticals. From a single-user, stand-alone application to a client/server, multi-user distributed architecture supporting the 4th Industrial Revolution era, FDT remains the only integration standard that works together with others, transforming the way industrial enterprises connect and communicate – sensor to cloud, by empowering the intelligent enterprise.