Remote connectivity to field devices, configuration and monitoring features

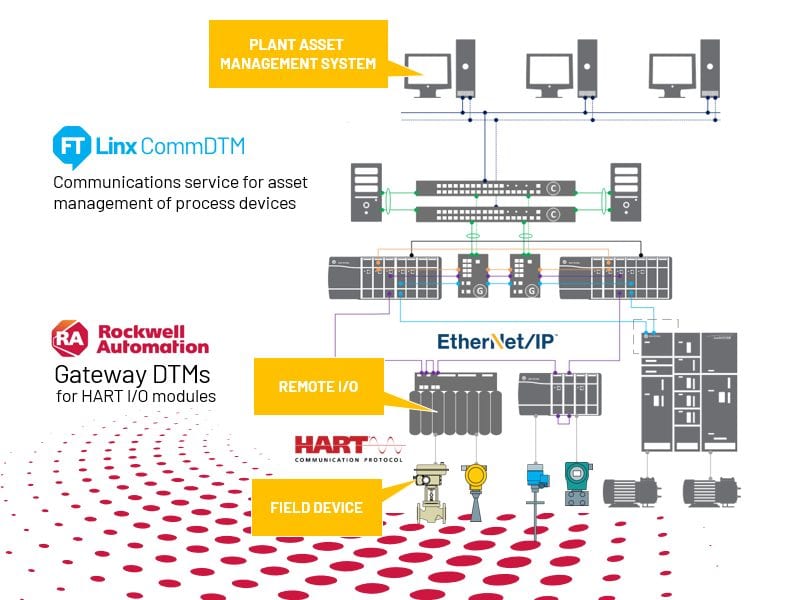

Process maintenance teams have long been challenged with gaining access and connectivity to service their field devices, like temperature sensors and valve actuators. To enhance plant operational efficiency, modern facilities want a fully enabled IIoT architecture that connects those devices to packaged automation solutions, plant-wide automation solutions and industry specific applications across the enterprise. To access plant floor data, Rockwell Automation® supports HART process devices in an FDT architecture with a variety of Gateway DTMs for the following HART protocol enabled I/O Modules: 1756, 1794, 1718, 1719, 1734 and 1769. Our latest additions include 1715, FLEX 5000™ and the AADvance® family.

Rockwell Automation, a leading provider of HART I/O solutions, is committed to providing access to HART device data with updated DTMs for all existing I/O platforms. The DTM enhancements provide users more visibility into the I/O platform performance, while enabling remote connectivity to HART field devices to manage configuration and monitor the diagnostic information according to recommendation NE 107 from NAMUR, a global association of process automation end users.

Inconsistencies in the availability of information to the teams of plant operators and technicians lead to different perspectives on how to optimize the facility. HART enabled I/O platforms can provide information that originates on the plant floor to both the real-time control system and the information-rich business and analytical systems. Using this standardized device health information in both communication channels allows both teams to make informed decisions based on historical performance and performance trends.

To download the latest FactoryTalk® Linx Comm DTM and the latest Gateway DTMs, please visit our Product Compatibility and Download Center (PCDC) click on “Find downloads” and search for “DTM”.

Product ad contribution provided by Rockwell Automation