NGL Producer Improves Commissioning, Troubleshooting and Safety with FDT Technology

Canadian company Inter Pipeline streamlines plant start-up and safety procedures with smart instrumentation information monitoring and asset management solutions

Device configuration and commissioning tasks are traditionally time-consuming, tedious, manual, and prone to errors. Yet, they are vital to ensure the reliability and safety of an industrial facility.

It has also been recognized time again that the ability to have open access to device intelligence is essential to enhanced reliability, reduced failures, and faster start-up times.

The following article describes how Inter Pipeline Ltd. recently commissioned a new liquids extraction plant with smart HART® devices, and used FDT technology to access information so as to effectively streamline pre-commissioning, configuration and troubleshooting of field instruments.

Background

Inter Pipeline is a major petroleum transportation, storage and natural gas liquids processing company based in Calgary, Alberta, Canada. It owns and operates facilities throughout western Canada and Europe.

In 2016, Inter Pipeline acquired a Canadian midstream business. The company now operates the Pioneer 1 and Pioneer 2 liquids extraction plants located near Fort McMurray, Alberta; a fractionator near Redwater, Alberta; and a pipeline system that connects these facilities.

The Pioneer 1 extraction plant, which began operations in 2002, processes offgas from oil sands upgraders. The Pioneer 2 plant began production in February 2016 and is committed to boosting domestic NGL production while reducing emissions of carbon dioxide (CO2) and sulphur dioxide (SO2).

Challenges with Field Devices

The “Connected Plant,” with its promises of smart equipment sharing data and allowing manufacturers to make informed business decisions, can only be a reality if instruments are properly set up and connected successfully to the plant’s network.

Commissioning and configuring field devices typically is one of the final, critical tasks before a plant can be formally started up. Accurate and timely completion of these tasks winds up being a critical hurdle prior to actual production.

Configuration and commissioning must be performed for each device – each with many configurable parameters. With countless devices in a typical process plant installation, technicians have mountains of data to enter and verify. For example, a typical guided wave radar level and interface transmitter has more than 500 parameters to configure.

During commissioning and start-up at Inter Pipeline’s Pioneer 2 facility, approximately 700 HART instruments from different suppliers were connected throughout the plant. However, intermittent failures occurred with specialized radar and magnetic level measurement instruments. These devices are part of a crucial safety control system in voted configuration, whereby taking sensor signals and comparing them in the central processing unit (CPU) executing the application logic accomplishes the voting elements.

Inter Pipeline’s Lead I&C Engineer, Japan Shah, stated, “Voting degradation on Pioneer 2’s safety system had the potential to cause unwanted downtime and also lowered confidence in the installed instrumentation. This situation was unacceptable to plant management, and created an urgent need to an effective device troubleshooting and maintenance solution.”

Integration and Data Delivery Agility

In order to optimize device configuration and commissioning, and ensure the continued safety of plant personnel and assets, Inter Pipeline’s project team employed FDT for smart instrumentation information monitoring. Recognized as an international (IEC 62453), North America (ISA 103), and China (GB/T 29618) standard, this enabling technology creates a common communication method between devices and control or monitoring systems for lifecycle management – to configure, operate, maintain, and diagnose intelligent assets.

Figure 2: Today’s “Connected Plant” can only be a reality if instruments are properly set up and connected successfully to the plant’s network.

Ongoing advancement of the FDT solution is leveraging major developments like the Industrial Internet of Things (IIoT) and Industrie 4.0 through the FDT IIoT Server (FITS) to help end users realize the true potential of decentralization, interoperability, integration, as well as a unified view of all data and functions across process, factory and hybrid control applications.

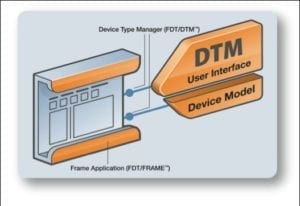

FDT technology is comprised of two main software components: the FDT Device Type Manager (FDT/DTM) and the FDT FRAME (FDT/FRAME). The FDT/DTM is a software component for an intelligent device or communication component within a digital network. It is similar to a device driver (like the driver used to set up a new printer), which is created by the instrument supplier who has the most knowledge of the full capability of the device. DTMs can range from a simple graphical user interface for setting device parameters up to a highly sophisticated application that can perform complex calculations for diagnostics and maintenance purposes. They include a rich and user-friendly graphical interface to make device configuration, maintenance, and troubleshooting fast and easy. Their simple and clear interface standardizes the training required to configure an intelligent field device – shortening set-up time and reducing configuration errors.

Conversely, the FDT/FRAME provides access to all devices, gateways and communication components with single-point access to operational assets. It can be embedded in any control system, configuration tool or engineering application that needs seamless access to the installed base of intelligent devices. This component allows DTMs to extract performance driven data from all connected devices and multiplexers on a control network.

Inter Pipeline used FDT/DTMs to ensure field devices were pre-commissioned and configured properly. Device manufacturers provide FDT/DTM software for their products, and the FDT/FRAME communicates and read those DTMs – regardless of protocol – for each device. This enables complete lifecycle access for configuration, operation and maintenance, no matter the supplier, device type/function, or communication protocol.

Figure 3: The FDT/DTM includes a rich and user-friendly graphical interface to make device configuration, maintenance and troubleshooting fast and easy.

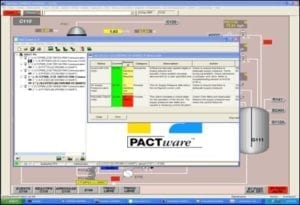

PACTware is a simple solution for device configuration, and at the same time, it provides a path from basic applications to complex asset management. The incorporation of .NET technology not only enables greater independence from the hardware platform, but also opens up new opportunities for a more advanced graphical user interface.

Addressing Instrument Failures

Inter Pipeline Instrument Technicians relied on a solution integrating DTMs with PACTware software to investigate, analyze and correct instrument failures, and in doing so eliminate spurious trips, during start-up of the Pioneer 2 facility.

Figure 4: Monitoring and troubleshooting of multi-vendor instruments at the Pioneer 2 facility was performed using PACTware software.

DTMs support a more robust diagnostic capability than Device Descriptions (DDs) and Electronic Device Description Language (EDDL), which provide minimal information on how to address malfunctions and configuration issues with smart instrumentation. The DTMs provide a handy tool for less experienced technicians to solve instrument problems in a short amount of time.

Device suppliers are able to embed intelligence in a DTM in a way that is very difficult to accomplish with DD files, such as a number of graphical constructs that cannot be expressed within DD technology. Moreover, the DTM is device and revision specific so that it has knowledge about the particular version of each device on the control network.

For example, magnetic level gauges installed at the Pioneer 2 plant have a DTM interface that provides a user-friendly troubleshooting menu. The ability to set sensitivity values through the intuitive DTMs helped resolve device performance issues and allowed for remote configuration, trending, and diagnostics.

In another instance, guided wave radar instruments had problems during tank filling. Personnel were able to adjust signal suppression and other parameters via DTMs. They gained visualization of echo curves, trends, and vessel configuration, along with the ability to store, review, save and e-mail data on instrument configuration.

Simon Huang, Lead E&I Tech for Inter Pipeline, believes FDT technology will provide an effective, long-term maintenance and operations solution for the Pioneer 2 facility. He said, “Our site maintenance teams now use DTMs as a day-to-day tool to tune a wide range of process and safety instruments –ensuring the plant runs without downtime, and, most importantly, stays safe. Personnel can remotely monitor the health of installed assets from a laptop in the control room without having to ensure harsh conditions in the field.”

Rakesh Keezhuveetil, DCS Engineer at the Pioneer 2 site, stated, “The combination of measured values and device diagnostics helps in identifying specific deviations in operation and instrument performance, and has substantially reduced troubleshooting time. This capability also allows the rapid segregation of the team that must act to address issues involving maintenance, operation, or processes. When an adverse situation arises, online information is crucial to mitigate the source of the problem.”

Conclusion

Inter Pipeline has continued to advance the innovation of the Pioneer 2 plant by achieving a flexible device configuration and commissioning capability, as well as a higher level of efficiency across its maintenance and troubleshooting work practices. Key to these improvements was the implementation of FDT technology to make certain all installed assets are used to the best of their ability. The facility has significantly reduced device commissioning cycle times and improved the quality of configuration. Operators, engineers and technicians can now be confident in the reliability of their plant’s safety system and instrumentation loops.